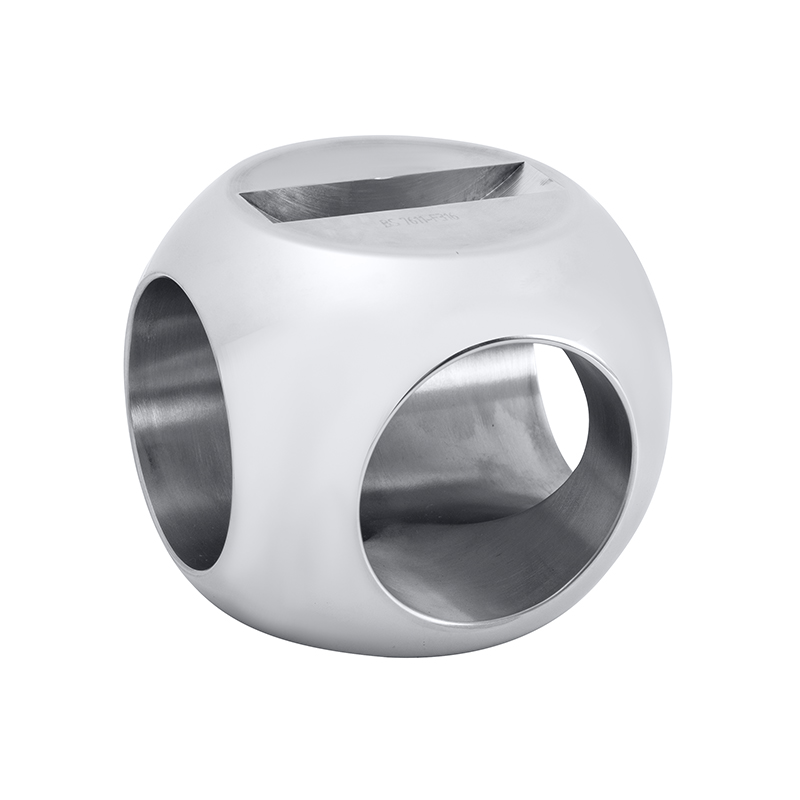

The industrial sector has shown increasing interest in upgrading the reliability and lifespan of core components. Among these, the valve sphere has become a central focus due to its essential role in fluid control systems. As operations become more demanding, ensuring the resilience of these parts is critical. New coating technologies are being introduced to reduce wear and corrosion, both of which can compromise the integrity of the valve sphere over time.

A typical through valve system relies heavily on the smooth operation of the valve sphere to regulate flow. Any surface degradation from friction or chemical exposure can directly affect its ability to maintain a consistent seal. This is particularly important in systems dealing with aggressive media or rapid cycling. To address these concerns, manufacturers have turned to thermal sprays, ceramic coatings, and hard chrome alternatives to provide better surface hardness and resistance.

Coating improvements are not only about extending service life but also about maintaining operational consistency. For example, in high-pressure through valve configurations, any deviation in the sphere’s surface geometry can result in leak paths or delayed response. With the application of wear-resistant layers, the valve sphere can retain its roundness and surface properties for longer periods. These layers are often engineered to match specific operating environments, including exposure to high temperature or reactive chemicals.

One area where coatings have had notable impact is in reducing maintenance cycles. In many pipeline networks or automated control setups, dismantling a through valve for inspection or part replacement can advance to operational downtime. A more durable valve sphere helps extend intervals between maintenance checks, contributing to smoother process control. Although no system is entirely maintenance-free, reduced intervention advances to cost benefits and less disruption.

The compatibility between the valve sphere coating and the seat material inside a through valve is another design factor under review. Engineers are now evaluating how new surface finishes influence sealing dynamics under different pressures. The interaction between moving and static parts must be balanced to avoid excessive friction while still achieving tight closure. Coating advancements allow for better control over these interactions by fine-tuning surface textures and hardness values.

In applications ranging from oil and gas to water treatment, the ability of a valve sphere to maintain function under adverse conditions is paramount. Corrosive fluids, sediment-laden flow, and thermal fluctuations all test the material’s limits. New coating strategies now include layered systems, where base and top coats serve different functions—such as a corrosion-resistant foundation beneath a wear-resistant exterior. This layered approach has shown promising results in preserving performance inside through valve assemblies.

Another aspect receiving attention is environmental compliance. Traditional hard chrome processes used for valve sphere coating are being phased out due to regulatory concerns. In their place, environmentally conscious coatings are being developed to meet durability targets without introducing harmful byproducts. This shift not only benefits the environment but also helps companies align with stricter operational standards.

As industries continue to rely on through valve mechanisms in a wide range of systems, the enhancements in valve sphere coating technologies stand out as a key step forward. While the fundamental design of these valves may remain stable, the materials and surface treatments used are clearly entering a new phase of innovation. This progress is shaping how fluid systems are engineered for resilience, responsiveness, and reduced maintenance requirements.

English

English Español

Español Deutsch

Deutsch