In fluid management systems, straightforward operation and reliable control are often crucial. The straight ball valve has become a favored choice in a range of sectors including water treatment, HVAC systems, and industrial piping. Its structure allows for a direct flow path, reducing resistance and offering a clear shut-off mechanism. As more industries focus on consistent flow regulation, the use of the straight ball valve has expanded in both small-scale setups and large infrastructure projects.

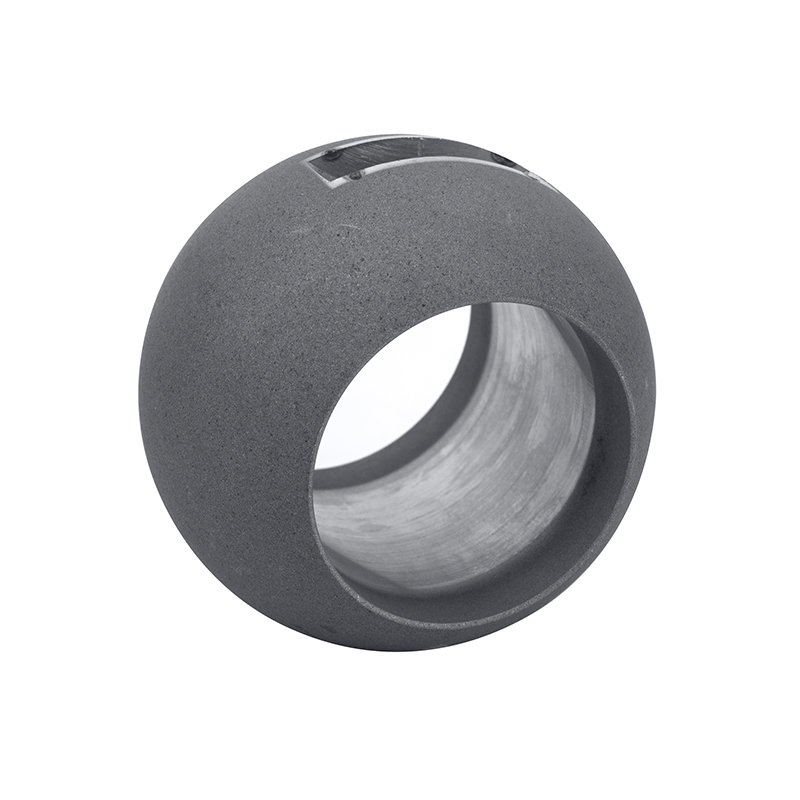

One of the defining features of the straight ball valve is its simple internal mechanism. Unlike more complex valve types, it uses a perforated ball that rotates to either allow flow or block it completely. This ease of operation is especially valued in systems that require rapid shut-off without the need for intricate controls. The straight-through design limits pressure drop, which can be critical in maintaining steady flow rates across interconnected components.

Supporting these valves are a wide variety of ball valve accessories. These include lockable handles, stem extensions, and actuator mounting kits. Accessories like these provide additional functionality, enabling users to tailor valve behavior to specific needs. For example, stem extensions allow easier access in installations where valves are placed in recessed or hard-to-reach locations. By integrating ball valve accessories, engineers can enhance usability without having to redesign existing systems.

Durability also plays a role in the increased adoption of the straight ball valve. Many of these valves are designed with corrosion-resistant materials, such as stainless steel or brass, which suit various fluid types. The straightforward design contributes to fewer moving parts, reducing the chance of internal failure or leakage over time. When paired with compatible ball valve accessories, these systems maintain their function in both high- and low-pressure environments, adding to their versatility.

Installation and maintenance are additional factors that influence equipment selection. A straight ball valve can typically be installed with small training due to its uncomplicated form. It is also compatible with standard piping sizes and layouts, making it an adaptable component across multiple use cases. With the help of standardized ball valve accessories, maintenance crews can perform repairs or modifications more efficiently, keeping systems operational with limited downtime.

While straight ball valves fulfill basic flow regulation tasks, their role becomes even more valuable when paired with precision components. For instance, position indicators and locking devices help improve control accuracy and safety in applications where misalignment or unintentional activation could pose risks. These accessories serve as practical enhancements rather than luxury add-ons, supporting the operational integrity of the valve.

Industries that prioritize flow regulation are paying closer attention to component compatibility. Ball valve accessories are often designed to fit a variety of straight ball valve models, streamlining procurement and inventory management. This interchangeability ensures that systems can be updated or maintained without disrupting operations or requiring custom-built solutions.

In practice, straight ball valves are proving useful in systems where simple control and fast response are priorities. Their growing presence reflects a practical shift toward components that balance functionality and ease of use. When supplemented with well-matched ball valve accessories, they offer a compact and durable solution for a wide range of fluid handling requirements. This adaptability helps meet performance expectations in a variety of environments, from residential plumbing to chemical processing setups.

English

English Español

Español Deutsch

Deutsch