As pipeline systems become more intricate across industrial sectors, the demand for adaptable flow control components continues to grow. Among these, the through valve has undergone significant design transformations to accommodate increasingly complex fluid management requirements. These developments are not only improving system compatibility but are also reshaping the way engineers integrate components like the valve sphere into broader pipeline infrastructures.

One key change in through valve design is the shift toward modular configurations. Unlike traditional fixed structures, newer versions are designed to be more easily incorporated into varied layouts, from compact installations to large-scale distribution networks. This versatility allows the through valve to support a range of applications, such as high-pressure transfer and chemical processing. The use of a valve sphere within these setups ensures smoother control over flow direction and volume, especially in systems where accuracy is essential.

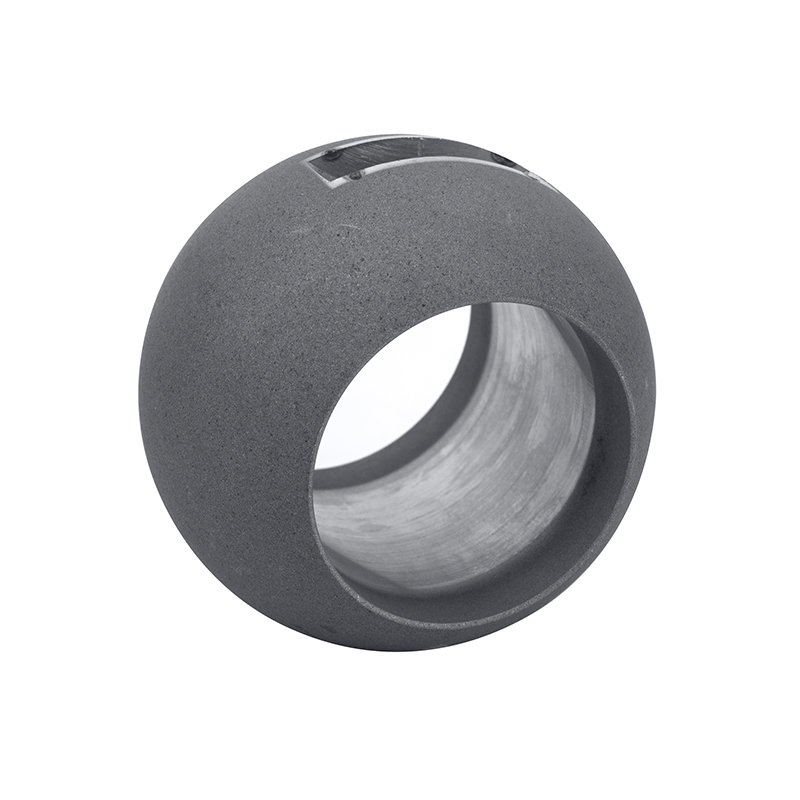

The valve sphere remains central to these functional improvements. Known for its rotational motion within a fixed casing, it helps regulate fluid passage without excessive wear on internal surfaces. In updated through valve assemblies, the sphere often features enhanced surface treatments and revised geometries that reduce turbulence and pressure loss. As a result, the combination of a durable valve sphere and a responsive through valve creates a reliable system for managing aggressive or variable flow conditions.

Material selection has also played a major role in recent advancements. Developers are increasingly turning to alloys and composite blends that can tolerate wider ranges of temperature and pressure. This shift benefits the valve sphere in particular, as it must withstand direct contact with both fluid and mechanical motion. Within a through valve configuration, materials must be resistant to corrosion, especially in oil, gas, or marine settings. These improvements allow the valve sphere to retain its integrity and functionality even after extended use.

Beyond materials, the integration of sensors and automation technologies is influencing the next generation of through valve systems. Smart monitoring systems can now be linked directly to the valve sphere, enabling real-time adjustments based on flow metrics or pressure readings. In industrial environments, this capacity is useful for less manual intervention while ensuring system responsiveness. The through valve becomes more than just a passive component—it contributes actively to the efficiency and safety of the overall operation.

Manufacturers are also responding to maintenance concerns by simplifying access points and streamlining replacement procedures. In certain designs, the valve sphere can be detached and replaced without dismantling the full through valve unit. This change reduces downtime during scheduled servicing and improves overall system resilience.

The evolution of through valve designs reflects broader industry trends toward flexibility, efficiency, and integration. As demands on pipelines grow more intricate, the role of components such as the valve sphere becomes increasingly important. By focusing on material durability, mechanical reliability, and smart functionality, designers are ensuring that the through valve remains a vital part of modern fluid control systems. With the valve sphere at its core, this technology continues to adapt to new challenges in pipeline infrastructure.

English

English Español

Español Deutsch

Deutsch