As fluid control requirements continue to evolve across industries such as energy, water treatment, and chemical processing, engineers are placing increasing emphasis on the development of compact systems. Among the components receiving renewed attention are the through valve configurations and the valve sphere elements that control flow within them. These parts are becoming central to the shift toward space-efficient design, where reducing system footprint without compromising performance has become a shared goal among manufacturers and engineers alike.

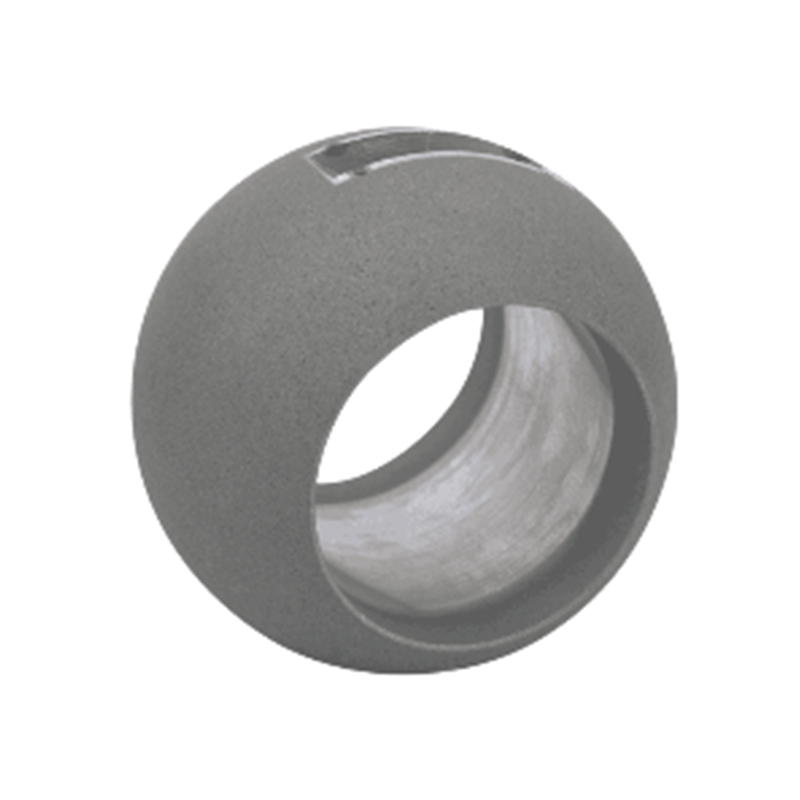

A through valve functions by allowing flow to move directly through its body with small restriction, offering predictable and consistent results. When integrated with a well-constructed valve sphere, this configuration supports applications that demand reliable shut-off or regulation, even in compact piping networks. The recent focus has turned toward reducing material usage and weight while maintaining strength and functionality, allowing such systems to fit into smaller enclosures or tighter mechanical spaces.

One of the driving forces behind this engineering direction is the growing demand for modular equipment. Systems that can be easily assembled or maintained in the field benefit greatly from components such as the through valve, which can be streamlined for rapid installation. The valve sphere, known for its rotational operation, is also being refined to match modern design needs. Surface treatments, new sealing mechanisms, and lighter-weight metals are among the innovations being explored to ensure these parts operate smoothly under diverse pressure conditions.

The balance between flow efficiency and size reduction is delicate. Engineers must consider how internal diameter, actuation force, and the geometry of the valve sphere will affect throughput. When a through valve is too compact, it may restrict flow or generate turbulence that compromises system efficiency. On the other hand, smart design adjustments—like repositioning the valve seats or adjusting the angle of the sphere—can help overcome these limitations without adding bulk to the system.

In manufacturing settings where space is at a premium, compact through valve assemblies are increasingly favored. For example, process skids, mobile filtration units, and compact heat exchangers often rely on integrated valves that take up as little space as possible. Here, the valve sphere plays a crucial role in ensuring that control remains consistent despite a reduced component footprint. The durability and sealing performance of these spherical mechanisms are being studied further to enhance long-term reliability in small-scale designs.

Serviceability is another area being addressed. As maintenance teams are often constrained by limited access points, the simplicity of compact through valve assemblies becomes an asset. Engineers are now designing systems that allow for the valve sphere to be easily removed or replaced without requiring disassembly of surrounding equipment. This not only less downtime but also reduces maintenance costs.

The continued push for system miniaturization is unlikely to slow down. As demand increases for portable, modular, and space-conscious equipment, components like the valve sphere and through valve will remain central to design strategies. Future developments are expected to explore composite materials, advanced flow modeling, and automation-compatible formats that will further enhance how these parts are integrated into compact systems.

The trend toward compact solutions is not just a temporary shift but a meaningful transformation in how engineers approach flow control. By refining the way the valve sphere interacts within a through valve, new opportunities emerge for innovation across multiple industries—creating solutions that are both space-efficient and functionally reliable.

English

English Español

Español Deutsch

Deutsch