In recent years, the global industrial valve market has been undergoing a quiet but meaningful shift. Buyers are no longer satisfied with surface-level specifications or catalog promises. Instead, deeper conversations are taking place across LinkedIn, industry forums, and procurement communities about where critical components are made and how consistently they perform. As a result, the role of a professional Valve ball factory and the practical value of the Hard Seal Ball are increasingly at the center of international sourcing discussions.

A Shift From Finished Valves to Core Components

Traditionally, many overseas buyers evaluated valves as complete assemblies. Today, that perspective is changing. Engineers and project managers are tracing performance issues back to their source, often discovering that the ball itself plays a decisive role in sealing stability, torque behavior, and service life.

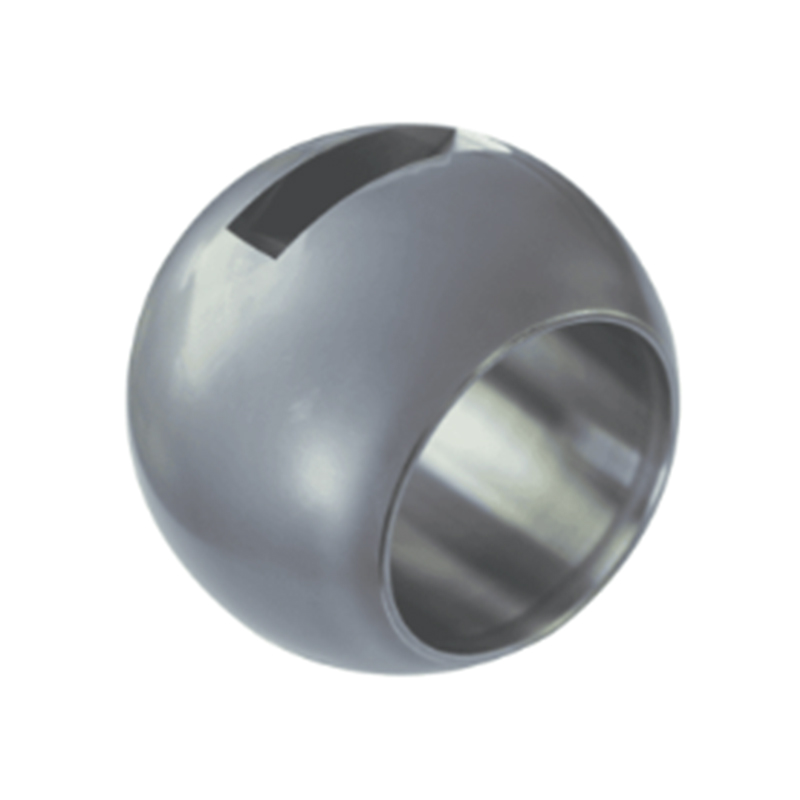

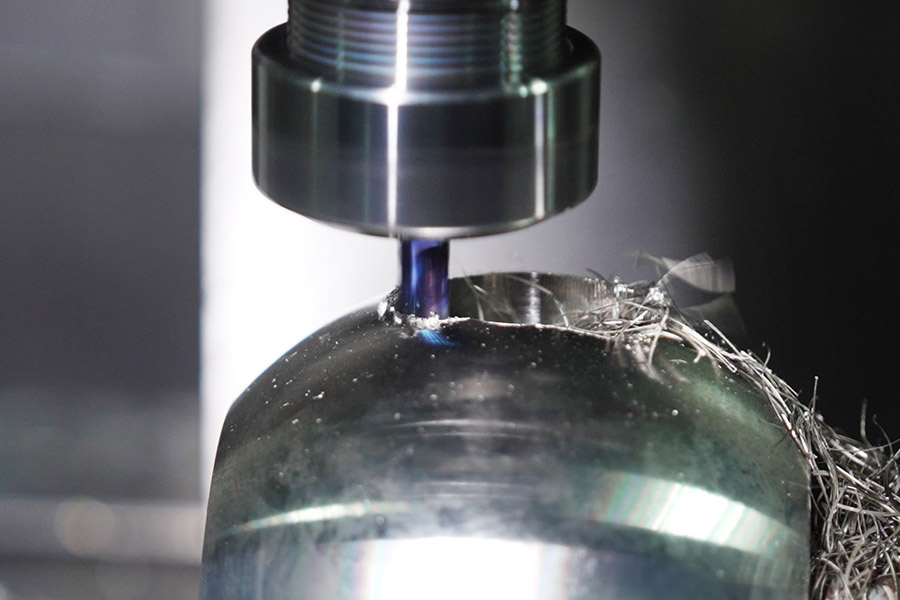

This shift has pushed valve balls out of the background and into the spotlight. Discussions now focus on machining accuracy, surface treatment methods, and the long-term compatibility between the ball and seat—areas where the capabilities of a Valve ball factory directly influence real-world outcomes.

Why Hard Seal Ball Solutions Are Gaining Wider Acceptance

Across industries such as oil and gas, chemical processing, power generation, and industrial pipelines, operating environments are becoming more demanding. Higher temperatures, fluctuating pressures, and complex media place greater stress on sealing components.

In response, Hard Seal Ball designs are being adopted more frequently because they are better suited for conditions where traditional soft sealing materials may struggle. However, overseas buyers increasingly recognize that performance does not depend on design alone. Manufacturing precision, material handling, and finishing processes all determine how a Hard Seal Ball behaves after extended use.

What Overseas Buyers Are Really Asking on Social Platforms

A review of overseas social media conversations reveals a clear pattern. Instead of asking only “What standard does it meet?”, buyers are asking:

- How stable is performance across multiple production batches?

- Can the supplier support customized surface treatments?

- What quality controls are in place during machining and inspection?

- How does the manufacturer ensure consistency for repeat orders?

These questions reflect a growing awareness that the Valve ball factory itself is a critical part of the value chain, not just a background supplier.

Manufacturing Process Transparency Builds Confidence

From a manufacturer’s perspective, transparency has become a key differentiator. Buyers want to understand how products are made, not just what materials are used. Clear explanations of production flow, inspection stages, and finishing techniques help reduce uncertainty during sourcing decisions.

For Hard Seal Ball products, this often includes insight into:

- Ball spherical accuracy control

- Surface hardening and polishing approaches

- Matching logic between ball and seat materials

Sharing this knowledge aligns expectations and positions the manufacturer as a long-term technical partner rather than a short-term supplier.

Why Content Depth Matters for Google Visibility

From a website operations perspective, in-depth, experience-based content performs better than purely promotional messaging. Google favors pages that answer real user questions, demonstrate expertise, and provide context around products.

Articles that explain how Hard Seal Ball performance connects to manufacturing practices, application demands, and sourcing considerations are more likely to earn sustained engagement and organic visibility. This approach also reflects how buyers research suppliers before initiating contact.

Long-Term Value Starts at the Factory Level

As industrial systems evolve, the importance of reliable valve components continues to grow. The performance of a Hard Seal Ball is not defined solely by drawings or materials, but by the manufacturing discipline behind it. For overseas buyers seeking dependable operation and stable supply, selecting a Valve ball factory with proven process control, application understanding, and communication transparency is becoming a strategic decision rather than a tactical one.

In this changing landscape, manufacturers who focus on quality consistency and technical clarity are well positioned to meet global expectations—today and in the years ahead.

English

English Español

Español Deutsch

Deutsch