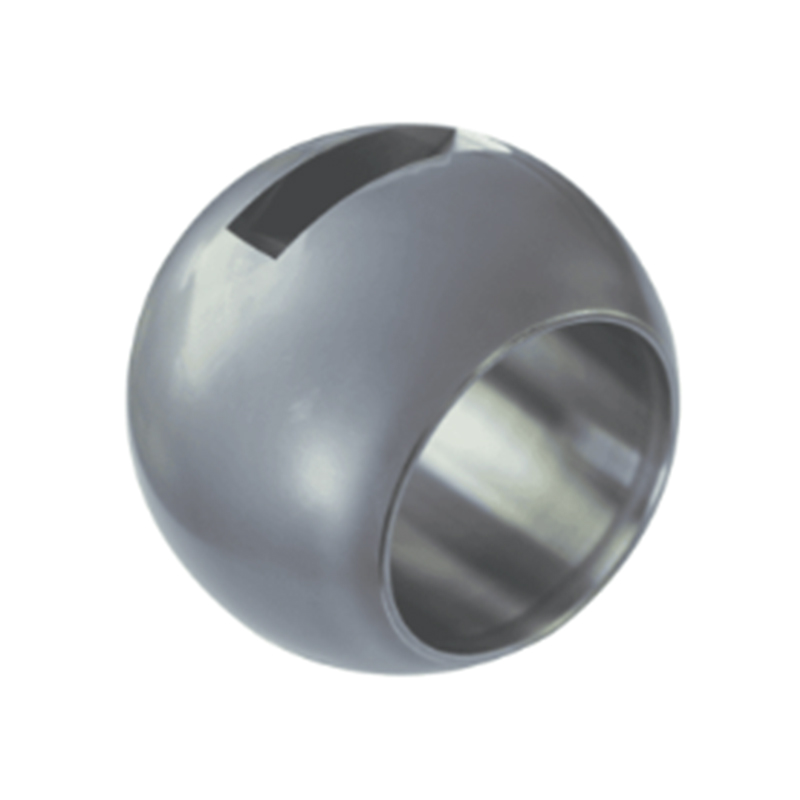

As global industries accelerate toward smarter infrastructure, cleaner energy systems, and more reliable flow control solutions, the Valve ball factory has become a growing focus across overseas markets. From oil and gas discussions on LinkedIn to water infrastructure conversations in engineering communities, buyers are paying closer attention to how core components are manufactured. At the center of these discussions lies one critical element: the Ball Valve Ball, a component whose precision, material stability, and surface quality directly affect system reliability and operational efficiency.

Global Demand Shift: Why Core Valve Components Matter

International buyers are no longer evaluating valves only as finished assemblies. Instead, attention has shifted toward internal flow-control components, particularly valve balls. Industry professionals increasingly recognize that leakage, torque instability, and premature wear often originate from insufficient machining accuracy or unsuitable material selection at the component level.

A modern valve ball factory is therefore expected to provide more than mass production. It must demonstrate process transparency, stable quality control, and the ability to support application-specific requirements across different industries.

Ball Valve Ball Performance and System Reliability

The Ball Valve Ball plays a decisive role in regulating flow, sealing pressure, and ensuring operational safety. In industries such as petrochemical processing, water treatment, HVAC systems, and industrial automation, even minor deviations in roundness or surface finish may influence sealing performance and long-term durability.

Key performance factors include:

- Sphericity consistency

- Surface roughness control

- Media compatibility

- Pressure and temperature adaptability

These elements explain why buyers increasingly prefer manufacturers that specialize in high-precision valve balls rather than generic components.

Manufacturing Trends in the Valve Ball Factory Sector

Across overseas manufacturing forums and B2B platforms, several trends are shaping purchasing decisions:

- Vertical integration for stable quality control

- Flexible production capability for customized specifications

- Process consistency across large and small batches

A professional valve ball factory typically manages forging, CNC machining, polishing, surface treatment, and inspection internally. This integrated approach improves traceability while reducing coordination risks for international buyers.

Material Selection and Application Matching Strategy

Material innovation remains one of the most discussed topics in valve engineering communities. Stainless steel, carbon steel, alloy steel, and specialized materials are selected based on operating pressure, flow media, and temperature range.

Rather than offering materials in isolation, an experienced valve ball factory supports customers by matching Ball Valve Ball materials to real-world operating conditions, reducing unnecessary costs and improving long-term performance stability.

Table 1: Common Ball Valve Ball Materials and Typical Applications

| Material | TypeTypical Applications | Key Performance Focus |

| Stainless Steel | Water treatment, HVAC, food processing | Corrosion resistance |

| Carbon Steel | Industrial pipelines | Structural stability |

| Alloy Steel | Oil & gas, high-pressure systems | Strength and durability |

| Special Alloys | Chemical processing | Media compatibility |

Precision Machining as a Trust Indicator

In international procurement discussions, precision machining is often directly linked with supplier credibility. Advanced CNC equipment, controlled heat treatment, and consistent polishing processes are essential to achieving smooth sealing surfaces and stable torque control.

Factories investing in machining accuracy enable:

Improved sealing performance

Reduced operational friction

Extended service life

These advantages appeal strongly to overseas buyers prioritizing reliability over short-term cost savings.

Surface Treatment and Sealing Performance Expectations

Surface finishing is another frequently discussed topic in global valve communities. Polishing, coating, and surface treatment processes influence wear resistance and sealing efficiency.

A professional valve ball factory maintains controlled finishing standards to ensure that every Ball Valve Ball performs consistently across applications without unnecessary complexity or overprocessing.

OEM Customization and Export Market Requirements

Customization is now a standard expectation rather than a premium option. Overseas OEM clients often request specific sizes, branding support, and tailored specifications.

Quality Control and Compliance Awareness

While buyers avoid exaggerated claims, they consistently seek clear inspection processes and stable quality systems. Structured quality control enhances trust and reduces sourcing risk, especially in cross-border procurement scenarios.

Factories that communicate inspection logic and production consistency naturally align with global expectations for responsible manufacturing.

Sustainability, Durability, and Lifecycle Value

Sustainability discussions increasingly focus on product lifespan and efficiency, not only environmental messaging. A high-quality Ball Valve Ball reduces leakage risk, maintenance frequency, and replacement needs, contributing to more efficient system operation over time.

This long-term value perspective resonates strongly with modern infrastructure developers and industrial operators.

Manufacturing Capability as a Long-Term Partnership Signal

In competitive international markets, buyers value manufacturers that emphasize technical understanding, consistency, and responsiveness. A valve ball factory that communicates clearly and supports engineering decisions builds trust beyond transactional supply.

This partnership-oriented mindset increasingly differentiates manufacturers in global markets.

The Future Direction of Valve Ball Manufacturing

As infrastructure systems grow more complex, demand for reliable internal valve components will continue to rise. Industry conversations are shifting from “who can supply” to “who can support performance over time.”

Manufacturers investing in precision, customization, and application understanding are best positioned to grow alongside their customers.

In today’s evolving flow-control landscape, the Ball Valve Ball is no longer a minor component—it is a defining factor in system reliability. Choosing a capable Valve ball factory means gaining a partner that understands materials, precision, and real-world applications, supporting long-term performance across global markets.

English

English Español

Español Deutsch

Deutsch