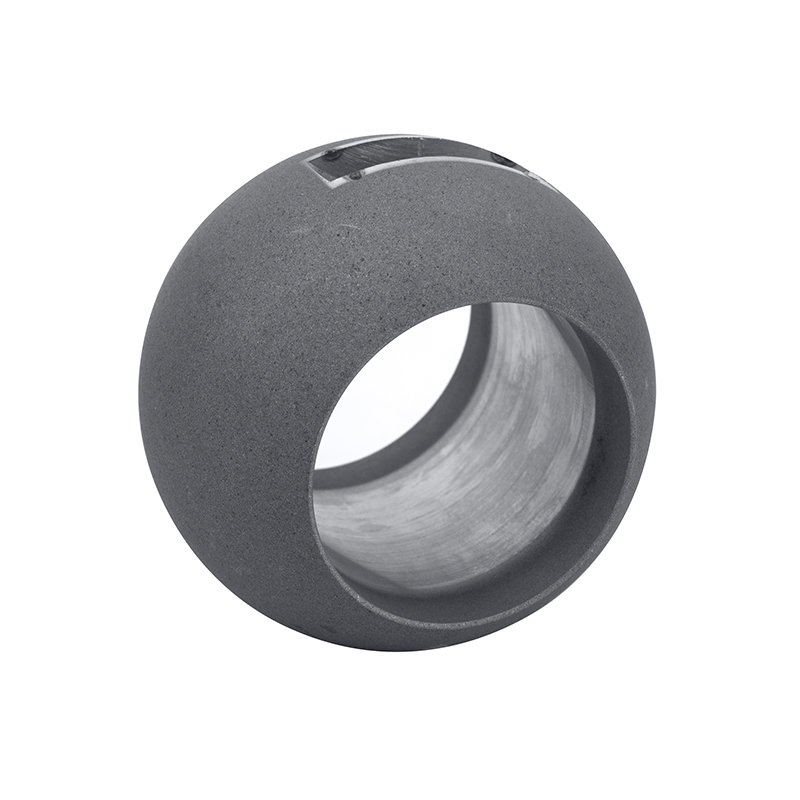

In today’s industrial landscape, Ball Valve Ball with hard coatings are emerging as essential components for companies seeking reliable and long-lasting performance. Industrial buyers are increasingly looking for solutions that withstand harsh conditions, ensure consistent sealing, and reduce maintenance demands. The combination of durability, precision, and optimized flow makes hard-coated Ball Valve Balls a strategic choice across sectors such as energy, petrochemical processing, and water infrastructure. Their performance advantages have sparked a growing interest among procurement teams aiming to improve operational stability while maximizing efficiency.

How Do Long-Cycle Operations Influence Buyer Decisions?

Modern industrial systems operate over extended cycles, often with minimal downtime. Components that cannot endure repeated operation or prolonged exposure to pressure, temperature, or chemical stress can compromise reliability. Hard-coated Ball Valve Balls offer superior surface protection, maintaining smooth operation and structural integrity over time. Buyers recognize that investing in durable valve components reduces unplanned interruptions, minimizes maintenance costs, and supports continuous production—key considerations in modern industrial planning and decision-making.

Can Optimized Design Improve System Stability?

Beyond durability, operational stability depends on precise design and surface quality. Hard-coated Ball Valve Balls provide smooth rotational performance and uniform sealing, reducing turbulence and stress on downstream equipment. Improved geometry and coating uniformity enhance system reliability, ensuring predictable fluid flow and pressure control. These performance benefits are particularly valuable in complex industrial systems, where even minor inconsistencies can lead to operational inefficiencies or safety concerns. Engineers increasingly prioritize valve balls that combine durability with high-precision design.

How Are Global Standards Shaping Buyer Expectations?

International engineering standards have raised the bar for component performance. Buyers now expect accurate machining, consistent surface finishes, and documented quality assurance. Suppliers that adhere to these standards instill confidence, offering verification through inspection reports and compliance certificates. The adoption of stricter safety and quality frameworks has accelerated the demand for hard-coated Ball Valve Balls, as they reliably meet or exceed the performance benchmarks expected in modern industrial projects.

What Role Do Digital Platforms Play in Procurement?

The rise of digital industrial platforms, webinars, and virtual trade exhibitions has transformed how buyers research valve components. Engineers can compare hard-coating processes, surface roughness, material quality, and field performance before making decisions. Case studies, instructional videos, and product demonstrations provide transparency, helping procurement teams make informed choices. This digital presence allows suppliers of high-quality Ball Valve Balls to reach a global audience and establish trust with buyers seeking long-term operational benefits.

Where Are Growth Opportunities Emerging?

Emerging industrial markets—including Southeast Asia, India, and the Middle East—are experiencing rapid infrastructure and energy sector expansion. These markets demand valve systems that perform reliably under variable conditions, including fluctuating pressures and harsh environmental exposure. Hard-coated Ball Valve Balls meet these requirements, offering reduced maintenance, extended service life, and consistent sealing. As industrial growth continues, demand for premium valve components is expected to increase, creating opportunities for suppliers who can deliver durable, precision-engineered solutions.

Why Combining Hard-Coated Ball Valve Balls with Hard Seal Balls Matters

Integrating hard-coated Ball Valve Balls with Hard Seal Balls provides a complete solution for modern industrial fluid systems. While the hard coating ensures surface durability and smooth flow, Hard Seal Balls enhance sealing performance under pressure variations. Together, these technologies reduce leakage risks, support system longevity, and improve overall operational safety. Buyers recognize that investing in both types of components delivers measurable benefits in terms of maintenance reduction, energy efficiency, and system stability, making the combination a critical choice in industrial projects.

From long-term reliability and operational stability to optimized flow and global adoption, hard-coated Ball Valve Balls have become indispensable for modern industrial systems. Their precision engineering, robust coatings, and compatibility with Hard Seal Ball make them an attractive solution for facilities aiming to enhance safety, minimize downtime, and improve efficiency. As industrial operations grow more demanding, the role of hard-coated Ball Valve Balls will continue to expand, cementing their position as a vital component in contemporary fluid-control strategies.

English

English Español

Español Deutsch

Deutsch