In today’s evolving water treatment industry, choosing the right components can significantly impact system performance. A specialized Valve ball factory is increasingly recognized as a key partner for ensuring efficiency and reliability. Engineers and procurement teams are prioritizing Water Treatment Ball Valve Ball precision, material durability, and long-term performance to meet stricter environmental and operational standards across municipal and industrial water systems. With increasing global focus on sustainable water management, the role of high-quality valve components has never been more critical.

The Role of Precision in Valve Ball Performance

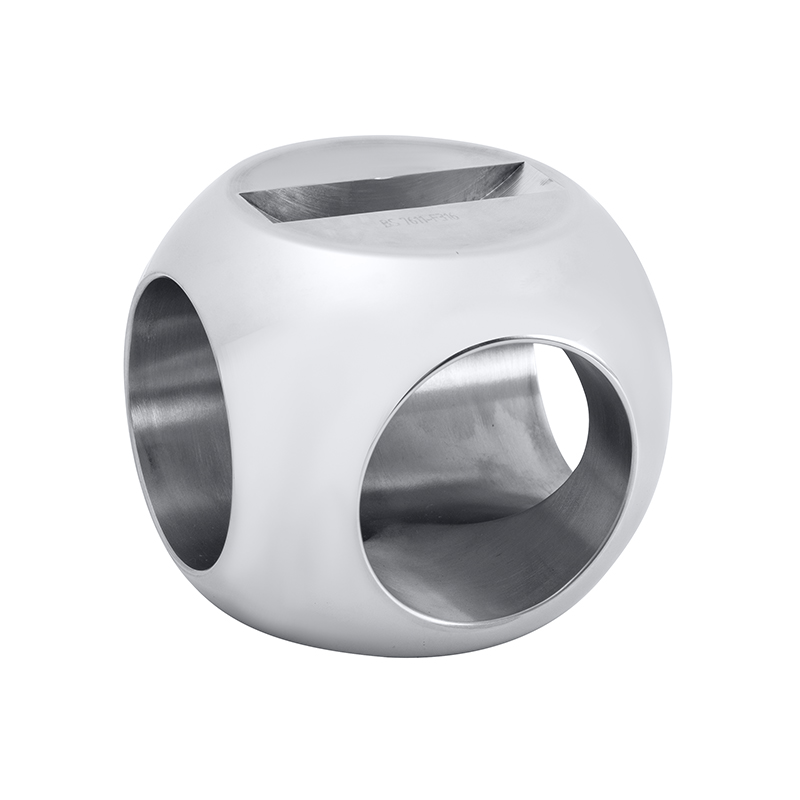

Valve balls are not just simple components—they are essential for flow regulation and sealing integrity. In water treatment systems, precise dimensions and high-quality surface finishes reduce leakage risks, minimize pressure drops, and enhance overall operational stability. Factories employing advanced CNC machining, controlled heat treatment, and polishing processes deliver the level of accuracy required for demanding installations. Modern treatment plants, especially those handling high-pressure or high-flow systems, benefit greatly from these precision-engineered components.

Material Selection and Resistance to Corrosion

Water treatment environments expose components to chlorinated water, chemicals, and varying temperature cycles. Selecting stainless steel, specialized alloys, or corrosion-resistant coatings can dramatically improve the service life of valve balls. Top-tier Valve ball factories guide clients through material selection, ensuring Water Treatment Ball Valve Balls are optimized for the specific chemical and physical conditions of each project. This material focus not only prevents premature wear but also ensures consistent performance over long operational periods, which is critical for both municipal and industrial applications.

Customization to Meet Diverse Industry Needs

Standard components are often insufficient for modern water infrastructure. Clients increasingly seek customized dimensions, surface coatings, and branded OEM solutions. Flexible manufacturing and consultative design allow valve ball manufacturers to provide tailored solutions, ensuring optimal performance in filtration systems, pump stations, pipeline networks, and desalination plants. This customization capability enhances system reliability, reduces maintenance downtime, and supports compliance with local and international water quality standards.

Applications Across Water Treatment Systems

From municipal water distribution to industrial wastewater processing, high-quality valve balls are critical for consistent operation. Properly engineered Water Treatment Ball Valve Balls withstand continuous flow cycles, variable pressures, and chemical exposure. By supplying precision-engineered components, manufacturers help operators maintain system efficiency, minimize maintenance, and reduce unplanned downtime. Their applications extend to cooling water systems in power plants, irrigation networks in agriculture, and treatment lines in chemical industries, highlighting their versatility.

Quality Control and Compliance

International buyers prioritize factories that implement strict quality assurance, inspection processes, and adherence to global standards. Traceability and batch consistency provide confidence for critical water treatment projects. Suppliers with robust quality systems ensure every Water Treatment Ball Valve Ball meets exacting specifications, supporting reliable and safe water management. Transparent documentation and testing reports also enhance trust and simplify integration into large-scale projects.

Sustainability and Long-Term Benefits

Durable valve balls contribute to sustainable water systems by reducing replacement frequency and minimizing material waste. Emphasizing corrosion resistance and consistent performance helps operators lower operational costs while maintaining high standards of efficiency. Leading Valve ball factories integrate sustainability into manufacturing, aligning long-term performance with environmental responsibility. Furthermore, energy-efficient production methods and recyclable materials are increasingly preferred by global clients seeking greener solutions.

Driving Water Treatment Excellence

High-quality Water Treatment Ball Valve Balls are foundational to efficient and reliable water systems. By combining precision engineering, material expertise, customization, and rigorous quality control, professional Valve ball factories enable water treatment operators worldwide to deliver safer, more sustainable, and cost-effective solutions. Investing in advanced valve technology ensures that water infrastructure remains resilient, reliable, and capable of meeting future demands.

English

English Español

Español Deutsch

Deutsch