Custom Ball Valve Balls are increasingly recognized as critical components in industrial fluid systems where standard, off-the-shelf solutions may not address specific operational challenges. As European industries—from chemical processing to food production—focus on optimizing process efficiency, reducing downtime, and extending equipment longevity, the role of precisely engineered valve components has gained renewed attention. This trend reflects broader movements toward customization and precision in industrial manufacturing, where one-size-fits-all approaches no longer align with the complex, varied demands of modern production lines.

Addressing Diverse Industrial Applications

Different industrial sectors present uniquely demanding requirements for valve performance, and custom ball valve balls are tailored to meet these niche needs. In the pharmaceutical industry, for example, valve balls must feature ultra-smooth surfaces that resist corrosion from aggressive sanitizing agents (such as peracetic acid) and prevent product residue buildup—critical for complying with EU GMP (Good Manufacturing Practice) standards. Meanwhile, in food processing facilities (like dairy or beverage plants), custom balls are manufactured from food-grade 316L stainless steel with electropolished finishes, eliminating crevices where bacteria could thrive. Even in oil and gas upstream operations, custom balls are designed to withstand high vibration and abrasive fluid mixtures (containing sand or crude particles), ensuring reliable flow control in offshore or onshore wellhead systems. This adaptability lets custom valve balls support consistent operation across vastly different industrial settings.

Material Selection for Specific Service Conditions

The operating conditions in industrial processes vary drastically in terms of pressure, temperature, and chemical exposure—and custom ball valve balls rely on targeted material selection to perform under these stresses. For high-temperature applications (such as steam-based power generation or industrial heating systems), manufacturers may use heat-resistant alloys like Inconel or Hastelloy, which maintain structural integrity even at temperatures exceeding 600°C. In corrosive environments, such as chemical plants handling acids or alkalis, custom balls are often crafted from super duplex stainless steel or titanium, materials with exceptional resistance to pitting and chemical degradation. For low-pressure, hygienic applications (like water treatment for municipal systems), food-grade plastics (such as PTFE-lined polyethylene) may be used to balance cost-effectiveness and performance. This material specificity directly supports valve lifespan, reducing the frequency of replacements in challenging operational environments.

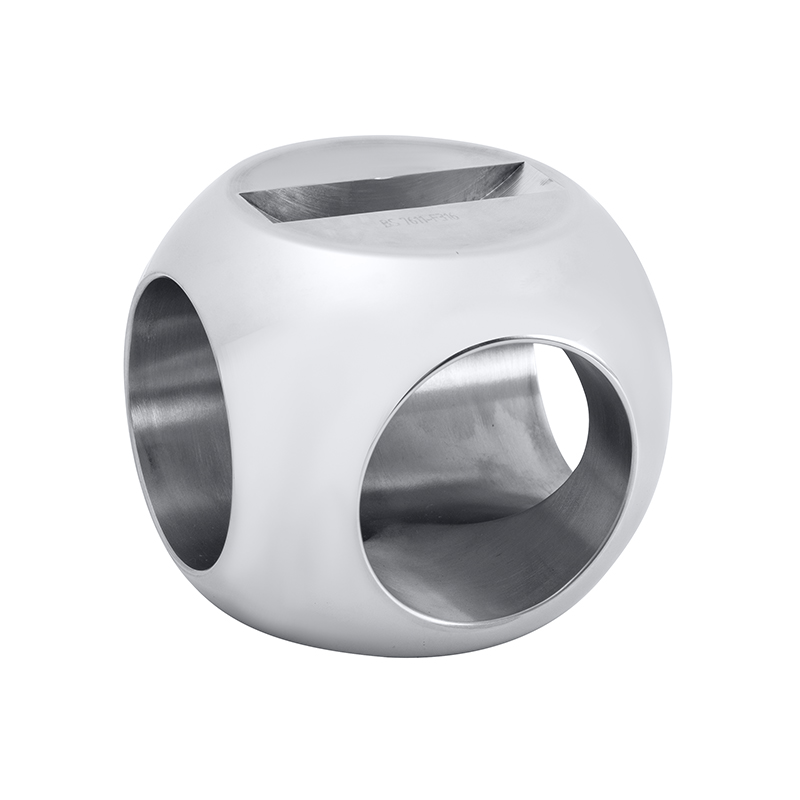

Precision Engineering for System Efficiency

The dimensional accuracy and surface characteristics of valve balls have a direct impact on sealing effectiveness and flow control precision—key drivers of system efficiency. Custom Ball Valve Balls are manufactured with micron-level tolerances (often as tight as ±0.005mm), ensuring a perfect fit with valve seats to minimize internal leakage. This level of precision is critical in processes where even small leaks can compromise product quality: for instance, in specialty chemical manufacturing, where cross-contamination from leaking fluids could ruin batches worth thousands of euros. Additionally, custom balls can be engineered with specialized surface textures (such as micro-polishing or coating with wear-resistant ceramics) to reduce friction, improving flow control responsiveness and lowering energy consumption—particularly in high-cycle applications where valves open and close hundreds of times per hour.

Supporting Maintenance and Retrofit Projects

Existing industrial facilities—many of which operate equipment installed decades ago—often require replacement valve components that either match original specifications or enhance performance without full system overhauls. Custom Ball Valve Balls excel here: for example, in a 40-year-old petrochemical plant in Germany, manufacturers produced custom balls to fit legacy valve bodies, matching the original 1980s-era dimensions while upgrading the material to corrosion-resistant alloy (replacing outdated carbon steel). This approach let the plant extend the valve’s lifespan by 10+ years without replacing the entire valve assembly, cutting maintenance costs by 40% compared to full replacement. Similarly, in wastewater treatment plants, custom balls can be tailored to fit non-standard valve sizes from older suppliers, ensuring continuity in critical fluid management processes without costly infrastructure upgrades.

Collaboration Between Manufacturers and Industrial Users

The development of effective custom valve ball solutions rarely happens in isolation—it relies on close dialogue between component manufacturers and industrial operators. This collaborative process typically starts with a detailed assessment of the user’s needs: for a pharmaceutical client, this might involve analyzing sanitization protocols and product contact requirements; for an oil and gas operator, it could include testing fluid samples to identify abrasive or corrosive elements. Manufacturers then create prototypes, which are tested in the user’s actual operational conditions (not just lab settings) to validate performance. For instance, a Spanish food processor and valve manufacturer collaborated to test three iterations of custom balls—adjusting surface finish and material thickness—before finalizing a design that met both hygiene standards and flow efficiency goals. This partnership ensures that Custom Ball Valve Balls address every specific challenge, from unique flow characteristics to long-term maintenance needs, rather than just meeting generic industry benchmarks.

English

English Español

Español Deutsch

Deutsch