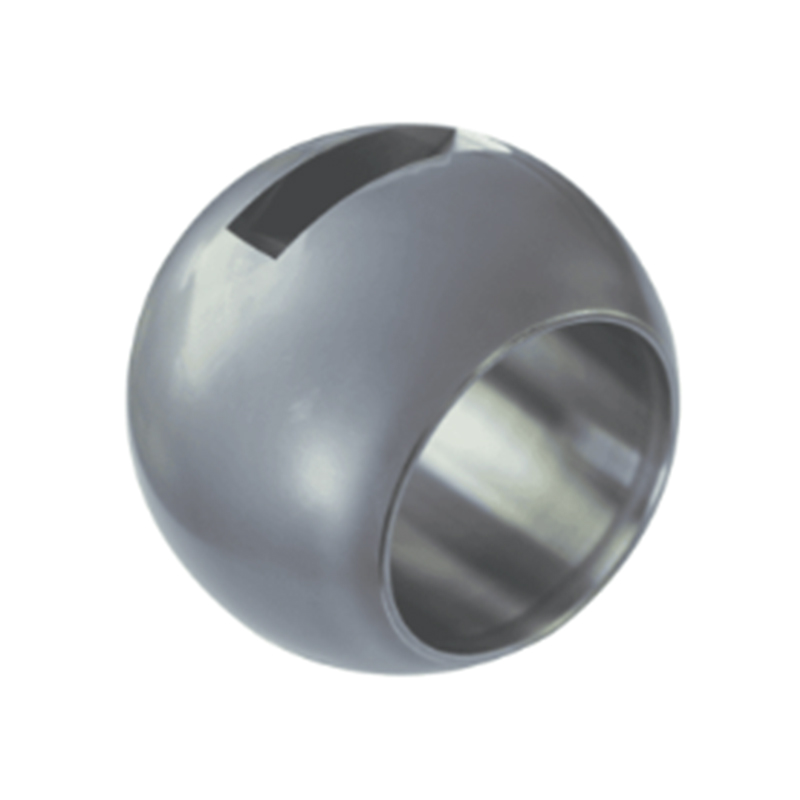

In today's industrial landscape, sustainability has become a crucial consideration across all sectors, including the manufacturing of kitchen tools and utensils and other essential equipment. Custom ball valve balls represent a significant advancement in industrial components that support environmental goals while maintaining high performance standards. These specialized components align with global sustainability initiatives such as the European Union's Circular Economy Action Plan and Sustainable Development Goal 9, helping industries reduce waste, lower carbon emissions, and improve operational efficiency through durable, long-lasting solutions.

Extending Equipment Service Life

The durability of custom ball valve balls directly impacts maintenance needs and replacement cycles, which are important factors in sustainable operations. Unlike standard components that may need frequent replacement, custom-engineered balls are made from materials specifically chosen for their working environment. This tailored approach significantly extends their usable life, reducing the need for manufacturing new components and minimizing waste. The longer these parts last, the fewer resources are consumed in producing replacements, contributing to more sustainable industrial practices.

Improving Energy Efficiency

Energy conservation is another key benefit of using custom ball valve balls in industrial systems. These precision-engineered components create better seals within valves, preventing leaks that can waste significant amounts of energy in fluid handling systems. When valves maintain tight seals, pumps and other equipment don't have to work as hard, resulting in lower energy consumption. This efficiency not only reduces operational costs but also supports environmental goals by decreasing the carbon footprint associated with energy use.

Ensuring Environmental Safety

Custom ball valve balls can be manufactured using materials that meet strict environmental and safety standards. In applications where contamination must be avoided, such as water treatment or food processing facilities, these components can be made from certified materials that prevent harmful substances from entering sensitive systems. This careful material selection helps protect environmental quality and public health while supporting industries in meeting regulatory requirements for safety and sustainability.

Supporting Circular Economy Principles

The design and application of custom ball valve balls align well with circular economy principles that emphasize reuse and resource efficiency. Because these components are engineered to fit existing valve systems, they enable repair and refurbishment rather than complete replacement of equipment. This approach conserves materials and reduces waste, extending the life of industrial infrastructure. Some manufacturers also offer recycling programs for used components, further supporting sustainable resource management.

Reducing Environmental Impact

The overall environmental benefits of custom ball valve balls extend throughout their lifecycle. From manufacturing through use and eventual replacement, these components are designed to minimize ecological impact. Their extended service life means fewer manufacturing operations are needed over time, reducing energy consumption and emissions associated with production. Additionally, the ability to refurbish existing valve systems with new balls rather than replacing entire assemblies significantly cuts down on material waste.

Adapting to Various Industrial Applications

Custom ball valve balls serve diverse industrial needs while maintaining their sustainability advantages. Whether in chemical processing, water management, or manufacturing facilities, these components can be tailored to specific operational requirements. This versatility ensures that different industries can benefit from their environmental advantages while maintaining the performance standards necessary for their particular applications.

English

English Español

Español Deutsch

Deutsch