In chemical processing plants, ensuring operational safety is a critical concern for engineers and operators alike. Among the numerous components that contribute to a secure and reliable system, Hard Seal Ball elements play a significant role in controlling fluid flow under demanding conditions. These components are commonly used in conjunction with at controls ball valves, creating a system that enhances both reliability and precision in chemical operations.

Durability Under Harsh Conditions

Chemical processing often involves handling aggressive fluids, high pressures, and bad temperatures. Hard Seal Ball components are specifically designed to withstand such challenges. The hard sealing surface maintains integrity even under corrosive environments, reducing the risk of leaks that could advance to hazardous situations. Unlike traditional sealing methods, which may degrade over time, hard seals provide consistent performance, helping plants maintain safer operational conditions.

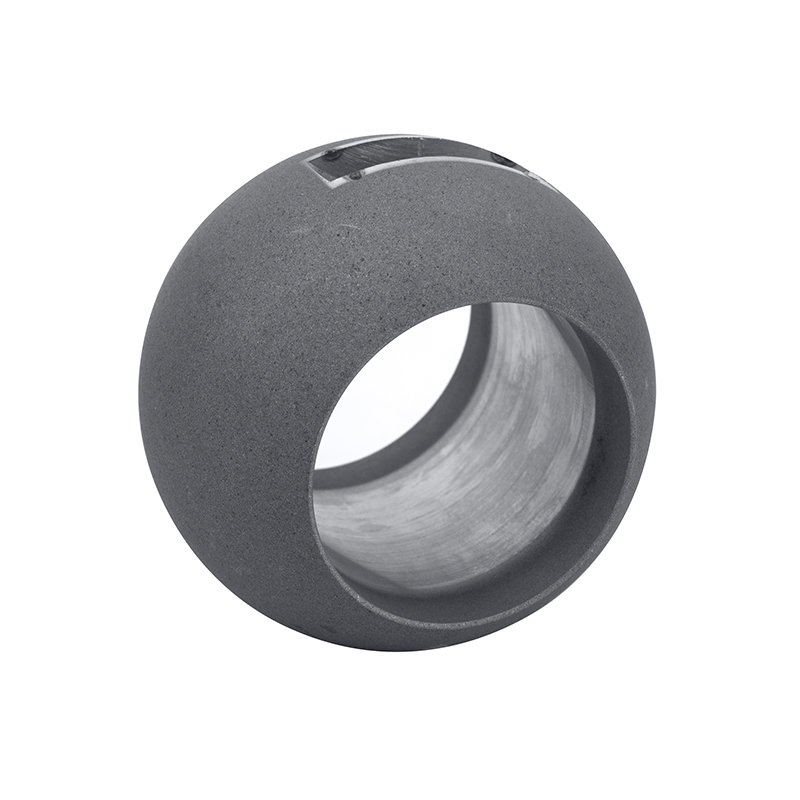

The material properties of Hard Seal Balls also play a vital role. Typically made from high-strength alloys or ceramics, these balls resist wear and chemical attack. This durability ensures that valves continue to operate effectively over extended periods, less unexpected maintenance interventions. When paired with at controls ball valves, the combination offers a stable solution for fluid regulation, even in systems where safety margins are critical.

Precision in Flow Regulation

Accurate control of chemical flow is essential for maintaining both process efficiency and safety. At controls ball valves, when integrated with Hard Seal Balls, provide precise modulation of flow rates. This precision helps prevent overpressure scenarios or uncontrolled reactions, which could otherwise compromise plant safety. The smooth movement of the Hard Seal Ball within the valve ensures that the flow can be adjusted predictably, contributing to consistent process outcomes.

Additionally, the sealing performance of Hard Seal Balls less leakage at the valve seat. Leakage not only represents a loss of valuable chemicals but also introduces potential exposure risks for plant personnel. By maintaining tight sealing characteristics, these components help mitigate environmental and safety hazards, supporting compliance with strict industry regulations.

Adaptability Across Applications

The versatility of Hard Seal Ball components allows their use in various chemical processes, including handling corrosive acids, solvents, and high-temperature fluids. At controls ball valves equipped with hard seals can manage these applications effectively, providing reliability where conventional sealing systems might struggle. This adaptability makes them suitable for both continuous production lines and batch processes, ensuring consistent safety standards across diverse operations.

In addition to process applications, Hard Seal Balls support operational safety during maintenance activities. The robust design reduces the likelihood of accidental leaks when valves are cycled or removed, contributing to a safer work environment for technicians. As chemical plants increasingly adopt rigorous safety protocols, components that inherently reduce risk become a practical necessity.

Long-Term Reliability

One of the key advantages of using Hard Seal Balls in chemical processing is their long-term reliability. Reduced wear and improved chemical resistance result in fewer valve replacements and service interruptions. When combined with at controls ball valves, the system not only provides accurate flow control but also helps maintain a stable process environment over extended periods. This reliability is particularly important in industries where even minor deviations in fluid handling can advance to costly or hazardous outcomes.

Hard Seal Balls are essential components that support safety in chemical processing by enhancing durability, precision, and long-term reliability. Integrated with at controls ball valves, they form a system that mitigates operational risks, maintains consistent performance, and adapts to a wide range of challenging chemical environments. Their presence in industrial systems underscores the importance of choosing materials and designs that prioritize both process integrity and the well-being of personnel.

English

English Español

Español Deutsch

Deutsch