The use of ball valves has seen significant growth across various industrial sectors due to their versatility and reliability in controlling fluid flow. Ball valves are known for their simple design and effective sealing capabilities, making them suitable for numerous applications. Central to their function is the valve sphere, which plays a crucial role in regulating flow through the valve body.

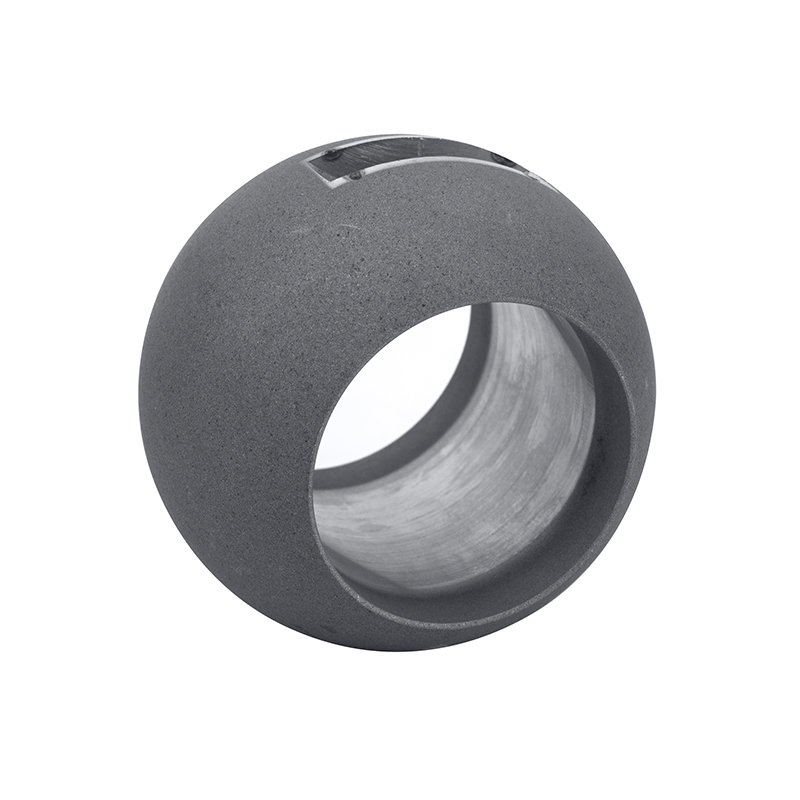

A ball valve consists of a hollow, perforated, and pivoting valve sphere that allows for quick shutoff and flow control. The valve sphere rotates within the valve body to open or close the flow path. This mechanism offers small resistance to flow when the valve is fully open and provides a tight seal when closed. Because of these characteristics, ball valves are widely used in industries ranging from oil and gas to water treatment and chemical processing.

One common type of ball valve is the fixed ball valve, which features a valve sphere fixed in position with respect to the valve body, allowing only the seat to move during operation. This design helps maintain alignment between the valve sphere and the seats, reducing wear and improving sealing performance. Fixed ball valves are particularly effective in handling high-pressure applications and fluids that may cause abrasion or corrosion.

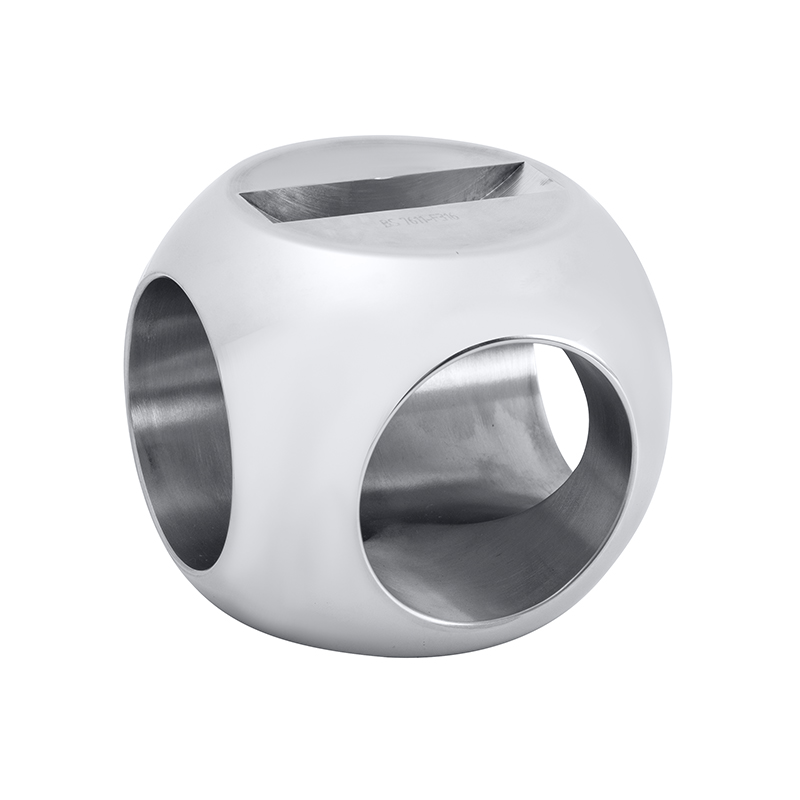

In addition to fixed ball valves, the 3 way T valve is another popular variant in industrial settings. The 3 way T valve incorporates a valve sphere with a T-shaped bore, which enables flow to be diverted or combined between three different ports. This design allows for greater flexibility in pipeline configuration and process control, making the 3 way T valve suitable for applications where multiple flow paths are required.

Industries such as petrochemical processing often rely on ball valves for their ability to withstand harsh environments and frequent cycling. The valve sphere, typically made from durable materials, ensures consistent performance even under corrosive conditions. Furthermore, fixed ball valves in these settings contribute to reduced maintenance needs by providing reliable sealing and less leakage risks.

Water treatment facilities also benefit from ball valve technology, particularly in managing large volumes of water with precision. The 3 way T valve allows operators to switch flows efficiently between different treatment stages or redirect water as needed without shutting down the system. The use of ball valves in these environments enhances operational efficiency and helps maintain system integrity.

Manufacturing plants often incorporate fixed ball valves within their process lines due to their robustness and ease of automation. The simple quarter-turn operation of a ball valve, controlled by the rotation of the valve sphere, enables quick response times in process adjustments. The 3 way T valve adds versatility, allowing for blending, diversion, or bypass functions within complex manufacturing systems.

The oil and gas sector also demonstrates extensive use of ball valves, including fixed ball valves and 3 way T valves, to manage the flow of crude oil, natural gas, and refined products. The valve sphere’s design helps maintain tight shutoff even under high pressure and temperature conditions, which is essential for safety and efficiency. Ball valves in this industry contribute to reducing downtime and operational risks by providing reliable flow control.

Ball valve applications are expanding steadily across various industrial sectors due to their adaptable design and functional advantages. The valve sphere remains a central component that determines the valve’s effectiveness in controlling flow. Both fixed ball valves and 3 way T valves offer unique features that meet specific needs within industrial processes. As industries continue to demand reliable and efficient fluid control solutions, ball valves will remain an integral part of system designs worldwide.

English

English Español

Español Deutsch

Deutsch