The evolution of valve technology continues to impact fluid control systems across many industries. Among these technologies, the valve sphere plays a critical role in enhancing the performance of various valve types, including the widely used ball valve. Recent developments in valve sphere design and materials have led to improvements in precision flow management, reliability, and durability. These advances contribute to more effective control solutions for applications ranging from industrial manufacturing to water treatment.

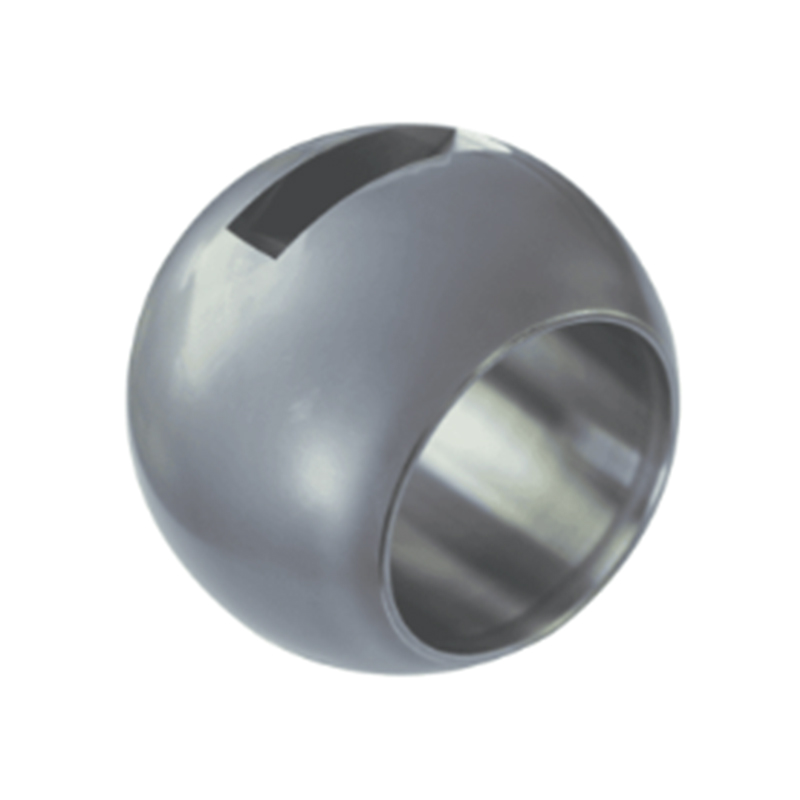

A ball valve operates by using a spherical component, the valve sphere, which rotates to regulate fluid flow. The valve sphere’s surface and material quality significantly influence the valve's sealing and operational efficiency. Innovations in valve sphere manufacturing have focused on improving surface smoothness and wear resistance, allowing ball valves to maintain tight seals over extended periods. This reduces leakage and contributes to more consistent flow regulation, which is essential in sensitive processes.

Fixed ball valves, a common variation in ball valve designs, benefit particularly from these improvements in valve sphere technology. In a fixed ball valve, the valve sphere is held in position within the valve body, with the flow path changing as the sphere rotates. The stability provided by the fixed configuration relies heavily on the precision and durability of the valve sphere. Enhanced materials and coating techniques have improved the resistance of valve spheres to corrosion and abrasion, which increases the service life of fixed ball valves even in demanding environments.

Another area where valve sphere advancements support precision flow management is in multi-port designs, such as the 3 way T valve. This valve type features a valve sphere with specially designed channels that allow fluid to flow between different ports depending on the sphere’s position. The complexity of flow paths in 3 way T valves demands high accuracy in valve sphere geometry and surface finish to prevent flow turbulence and leakage. Recent progress in machining and surface treatment has made it possible to produce valve spheres that meet these stringent requirements, resulting in smoother operation and more accurate flow direction.

The materials used for valve spheres continue to evolve as well. Traditional valve spheres were often made from stainless steel or other metals, but new composites and advanced alloys offer improved resistance to chemical corrosion and mechanical wear. These material upgrades have been incorporated into ball valves and fixed ball valves, enhancing their applicability across a broader range of fluids and operating conditions. The ability of valve spheres to withstand harsh environments without compromising performance is a key factor in expanding their use in sectors such as chemical processing and oil and gas.

Maintenance and operational efficiency are also impacted by these advances in valve sphere technology. Improved surface finishes reduce friction during valve operation, pilot to easier actuation and less wear on seals and seats. This is particularly important for the 3 way T valve, where the valve sphere’s movement is more complex compared to standard ball valves. Reduced maintenance needs and increased reliability contribute to lower operating costs and longer intervals between service cycles.

In addition to functional benefits, advances in valve sphere manufacturing support more consistent quality control. Precision machining and advanced inspection techniques allow manufacturers to produce valve spheres with tight dimensional tolerances, which is essential for ensuring the proper fit and sealing performance within ball valves, fixed ball valves, and 3 way T valves. Consistency in valve sphere production translates to valves that perform reliably across different batches, providing confidence to system designers and operators.

The continued development of valve sphere technology plays a significant role in supporting precision flow management across various valve types. Ball valves, fixed ball valves, and 3 way T valves all benefit from improved valve sphere materials, surface finishes, and manufacturing precision. These advances help enhance sealing performance, durability, and operational efficiency, making these valves more suitable for a wide range of industrial applications. As industries demand increasingly reliable and accurate fluid control solutions, progress in valve sphere technology will remain a key factor in meeting those needs.

English

English Español

Español Deutsch

Deutsch