In the valve manufacturing industry, the choice of materials used for the valve sphere plays a significant role in determining the overall durability and performance of valves. Among various valve types, the Ball Valve is widely utilized in many applications due to its simple operation and reliable sealing. The materials chosen for the Valve Sphere, which is the key component inside the Ball Valve, can greatly impact the valve's lifespan and resistance to wear, corrosion, and pressure.

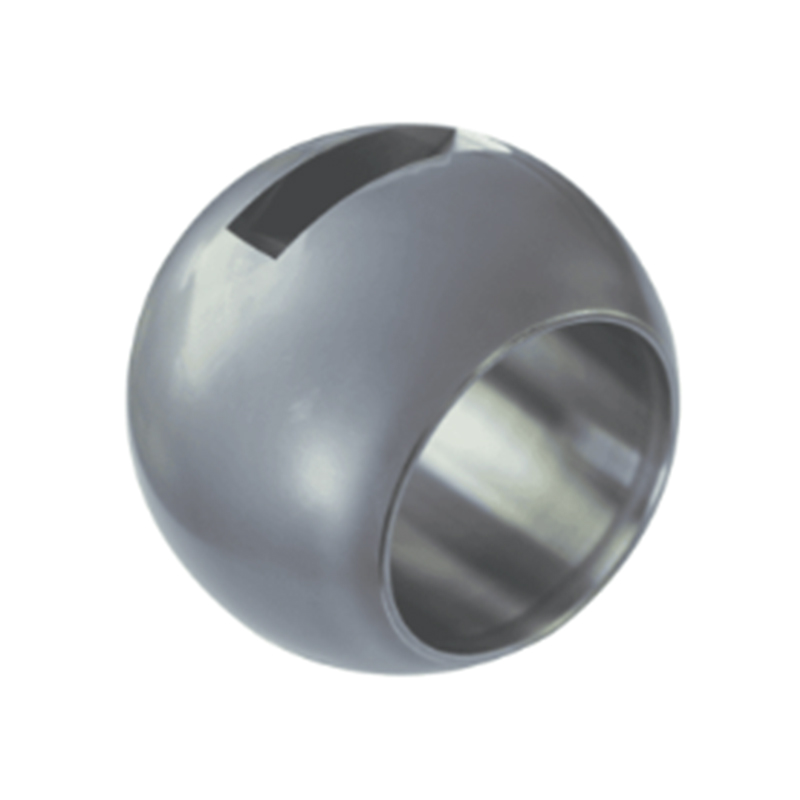

Ball Valves function by rotating a spherical element—the Valve Sphere—with a bore through it to control flow. When aligned, the bore allows fluid to pass through; when turned, it blocks flow. This mechanism depends heavily on the quality and durability of the Valve Sphere. Materials traditionally used for Valve Spheres range from stainless steel to various alloys and composites, each offering different benefits for specific environments.

One common variant is the fixed ball valve, where the Valve Sphere remains securely held within the valve body, ensuring stable operation under different pressures and temperatures. The fixed ball valve design reduces the risk of sphere displacement, which can advance to leakage or failure. The material properties of the Valve Sphere in fixed ball valves are crucial because the component must withstand mechanical stress and maintain a smooth surface to ensure tight sealing.

Advances in materials science have introduced new alloys and coatings that enhance the resistance of Valve Spheres to corrosion and abrasion. For instance, some Valve Sphere materials are now designed to resist chemical attack in harsh industrial fluids, extending the operational life of Ball Valves in chemical plants or wastewater treatment facilities. These material improvements also help fixed ball valves maintain performance consistency over time.

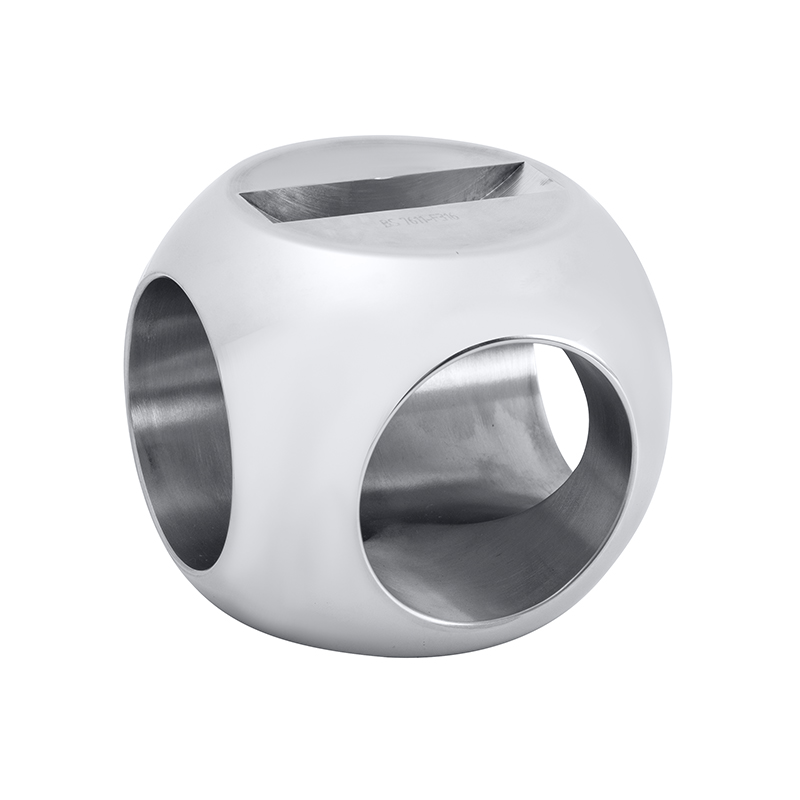

Another important valve type is the 3 way T valve, which features a Valve Sphere with multiple ports allowing fluid to flow in different directions. The material quality of the Valve Sphere in a 3 way T valve is especially important because it must endure the mechanical complexity of flow diversion without degrading. The spherical design must retain its shape and surface finish despite frequent switching between flow paths.

Material choices for Valve Spheres in 3 way T valves often focus on balancing strength, corrosion resistance, and cost-effectiveness. Using advanced stainless steel alloys or composite materials can help achieve this balance. The durability gained through these material choices less maintenance needs and reduces downtime in systems employing 3 way T valves.

Ball Valve manufacturers also consider surface treatments on Valve Spheres to further improve wear resistance. Hardening techniques, such as chrome plating or nitriding, can enhance the durability of Valve Spheres, particularly in fixed ball valve configurations. These surface enhancements protect the Valve Sphere from scratches or pits that might compromise sealing integrity.

Durability improvements in Valve Sphere materials have ripple effects on the performance of the entire valve assembly. For Ball Valves, a robust Valve Sphere ensures consistent sealing, reduces leakage risks, and improves operational reliability. Fixed ball valves benefit from the stable positioning of a durable Valve Sphere, helping maintain performance even in demanding applications.

In the case of 3 way T valves, the enhanced materials allow for smoother flow control and increased valve life. This is particularly valuable in industrial systems where fluid direction changes frequently, and valve downtime can impact productivity. The ability of Valve Spheres to maintain their physical and chemical properties over time contributes significantly to overall system efficiency.

The development of new materials for Valve Spheres is driving improvements in the durability and functionality of Ball Valves, fixed ball valves, and 3 way T valves. By selecting materials that resist corrosion, wear, and mechanical stress, valve manufacturers can provide solutions that meet the evolving demands of industrial applications. The Valve Sphere remains a critical component whose material quality directly influences valve performance, making material innovation a key focus in the valve industry.

English

English Español

Español Deutsch

Deutsch