In today’s rapidly evolving industrial landscape, global buyers are paying closer attention to where critical components come from and how they are made. Discussions across LinkedIn engineering groups, industrial forums, and procurement communities increasingly highlight one essential link in the supply chain: the Valve ball factory. Once treated as a background supplier, the valve ball manufacturer is now recognized as a key contributor to valve reliability, system safety, and lifecycle performance in international projects.

The Rising Importance of Internal Valve Components

Overseas markets are undergoing a noticeable mindset shift. Instead of focusing only on external valve specifications, buyers are evaluating internal components that directly influence sealing, torque, and durability. Engineers frequently point out that failures in ball valves often originate from internal inconsistencies rather than external housing defects.

This awareness has elevated the valve ball from a simple mechanical part to a performance-critical component. As a result, manufacturers with specialized expertise are gaining increased attention from global customers seeking long-term operational stability.

Manufacturing Authority Rooted in Specialization

From a manufacturer’s perspective, true authority comes from focus. A dedicated valve ball factory concentrates its resources on mastering geometry control, surface treatment, and material behavior rather than spreading attention across unrelated products.

This specialization allows for:

- Deeper understanding of application-specific requirements

- Faster response to custom design needs

- Continuous refinement of production techniques

Such focus is increasingly valued by overseas OEMs and distributors who prefer stable, knowledgeable partners over general suppliers.

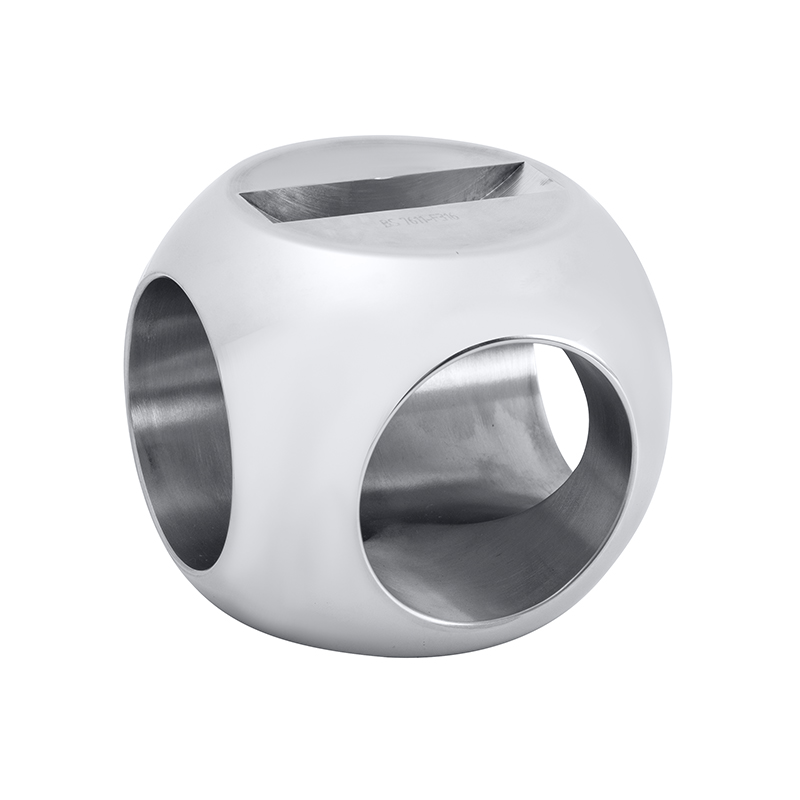

Precision Geometry: More Than Just Roundness

One of the most discussed topics among international valve engineers is geometric precision. While roundness is essential, modern applications demand far more detailed control.

Critical geometric considerations include:

- Sphericity consistency across batches

- Accurate bore alignment

- Uniform wall thickness for pressure balance

Even minor deviations can lead to uneven seat contact, increased torque, or accelerated wear. Manufacturers that invest in precision machining and measurement systems help eliminate these hidden risks before products reach the field.

Surface Engineering and Operational Performance

Surface quality is often underestimated until problems arise. Overseas maintenance teams frequently report that unstable sealing or leakage issues correlate with inconsistent surface finishes on valve balls.

From a production standpoint, controlled surface engineering delivers several advantages:

- Improved sealing integrity

- Reduced friction during operation

- More predictable wear patterns

Advanced polishing and finishing processes allow manufacturers to align surface characteristics with the intended valve seat material, enhancing overall system harmony.

Material Selection Driven by Real-World Conditions

Global applications vary widely, and material choice must reflect real operating environments rather than generic standards. Buyers increasingly ask manufacturers for guidance rather than simply requesting a standard grade.

Below is an overview of common material considerations:

| Material | CategoryCommon Industries | Functional Focus |

| Stainless Steel | Water, food, chemical processing | Corrosion resistance |

| Carbon Steel | General pipelines, utilities | Structural strength |

| Alloy Steel | Energy, high-pressure systems | Thermal and pressure stability |

A manufacturer’s ability to recommend appropriate materials based on experience strengthens trust and reduces downstream issues.

Customization as a Competitive Advantage

Customization has become a defining factor in international cooperation. Standard products may meet basic needs, but many projects require tailored solutions due to space constraints, unique media, or specialized valve designs.

Typical customization requests include:

- Non-standard diameters

- Special surface coatings

- Adjusted tolerances for automated systems

A valve ball factory with in-house engineering and flexible production lines can support these requests efficiently, helping customers maintain project timelines.

Application Scenarios Shaping Market Demand

The global demand for high-quality valve balls is closely tied to infrastructure and industrial expansion. Based on manufacturer-side export experience, key application areas include:

- Oil and gas transportation

- Water treatment and desalination

- Chemical processing facilities

- Power generation systems

- Industrial automation networks

Each sector places unique demands on valve components, reinforcing the need for adaptable manufacturing capabilities.

Quality Control as a Continuous Process

International buyers increasingly expect more than final inspection certificates. They want assurance that quality is embedded throughout production.

From a manufacturing standpoint, effective quality control typically involves:

- In-process dimensional checks

- Surface roughness monitoring

- Batch traceability systems

These practices reduce variability and ensure that every shipment meets consistent performance expectations, regardless of order volume.

Transparency Builds Confidence in Overseas Markets

Trust is a recurring theme in global procurement discussions. Buyers want transparency in production methods, testing standards, and communication.

Manufacturers who openly share process insights, application experience, and technical guidance often build stronger relationships. Transparency is no longer just a marketing advantage—it is a competitive requirement.

Sustainability Considerations in Component Manufacturing

Although valve balls are industrial components, sustainability is becoming part of purchasing criteria. Overseas customers increasingly value manufacturers who demonstrate responsible resource usage.

Efficiency-driven production, optimized machining cycles, and reduced material waste contribute to both environmental responsibility and cost stability. These practices align well with global sustainability trends without compromising performance.

Adapting to the Future of Smart Flow Control

As industrial systems become more automated and data-driven, valve components must perform consistently under continuous monitoring. Smart systems quickly detect torque changes, leakage, or wear, leaving little margin for inconsistency.

This future places higher demands on valve ball manufacturing, encouraging:

- Tighter tolerances

- More consistent surface finishes

- Stronger collaboration between manufacturers and valve designers

Factories that invest early in precision and process optimization are better positioned for long-term global competitiveness.

Manufacturer Insight: Why Experience Still Matters

While new technologies attract attention, manufacturing experience remains irreplaceable. Years of production feedback, application learning, and problem-solving enable manufacturers to anticipate issues before they occur.

From a manufacturer’s viewpoint, experience translates into reliability—something overseas buyers value when selecting long-term partners.

The Strategic Value of a Trusted Manufacturing Partner

Behind every reliable valve system is a component supplier that understands both engineering principles and real-world applications. A precision-made Ball Valve Ball reflects the capabilities, discipline, and expertise of its manufacturer. As global industries continue to prioritize durability, safety, and lifecycle value, choosing a specialized valve ball factory becomes not just a sourcing decision, but a strategic investment in long-term flow control performance.

English

English Español

Español Deutsch

Deutsch