The global shift towards renewable energy has accelerated the demand for advanced components that ensure efficiency, reliability, and safety within energy systems. Among these components, superior ball valves play a critical role in controlling the flow of fluids in various renewable energy infrastructures such as wind turbines, solar power plants, bioenergy systems, and hydropower installations. This article explores the increasing demand for advanced ball valves, the integration of automated ball valves, and the application of 3 way stainless steel ball valves in renewable energy sectors.

The Role of Ball Valves in Renewable Energy

Ball valves serve as essential control devices that regulate the flow of liquids and gases. Their ability to provide tight sealing and quick shut-off makes them suitable for systems where flow control accuracy and durability are vital. Renewable energy applications often involve harsh operating conditions, such as fluctuating pressures, temperature variations, and corrosive environments. This makes the choice of valve technology crucial for ensuring long-term system stability.

Advanced Ball Valves: Durability and Reliability

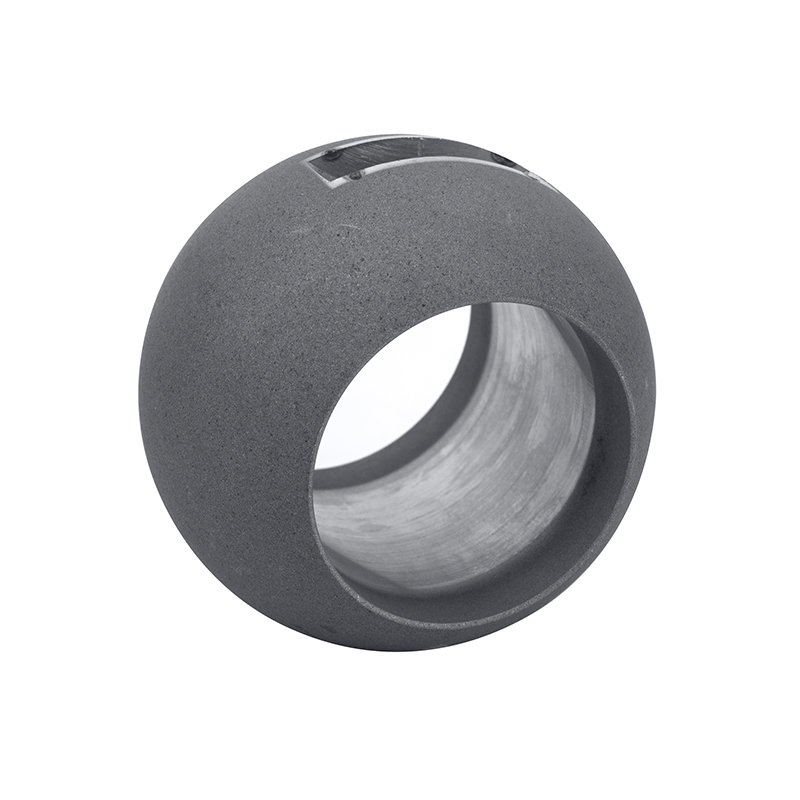

In renewable energy installations, valves must withstand various stressors without compromising performance. Advanced ball valves, designed with high-quality materials and precise manufacturing processes, offer reliable sealing and resistance to wear and corrosion. The materials often include stainless steel or specially coated alloys that resist oxidation and chemical degradation, common in bioenergy plants and hydropower facilities.

Advanced ball valves also provide smooth operation with small torque requirements. This reduces the mechanical wear on valve components and enables easier integration with automation systems. The robust design ensures that valves maintain their integrity under frequent operation cycles, which is essential in energy systems requiring constant adjustment and maintenance.

Automated Ball Valve: Enhancing Efficiency and Control

Automation in valve technology has become a key driver in modern renewable energy systems. Automated ball valves are equipped with actuators—either electric, pneumatic, or hydraulic—that allow remote or programmed control of valve positions. This integration enhances operational efficiency, reduces manual intervention, and improves system safety.

In solar power plants, for instance, automated ball valves regulate the flow of cooling fluids that maintain good temperatures for photovoltaic panels and inverter equipment. In wind turbines, these valves help manage lubrication and hydraulic systems with precision, less downtime, and maintenance costs.

Moreover, automated ball valves enable real-time monitoring and feedback, which is critical for predictive maintenance and system optimization. Through advanced control systems, operators can quickly respond to changes in flow demand or detect early signs of valve wear, thus avoiding potential failures or energy losses.

The Versatility of 3 Way Stainless Steel Ball Valves

3 way stainless steel ball valves offer flexibility that suits complex fluid handling needs in renewable energy applications. These valves have three ports, allowing flow to be directed in multiple ways, which can be essential in systems requiring fluid diversion, mixing, or selective isolation.

In bioenergy plants, 3 way stainless steel ball valves are often used to switch between different fuel inputs or divert waste streams for processing. Their corrosion-resistant properties make them suitable for handling biofuels and other aggressive fluids.

In hydropower systems, 3 way valves facilitate the management of water flow between different channels or turbines, ensuring balanced distribution and pressure regulation. The stainless steel construction offers durability against erosion caused by high-velocity water and particulate matter.

Additionally, these valves support system compactness and reduce the need for multiple separate valves and pipe fittings. This simplifies installation and lowers overall system costs.

Future Trends and Challenges

The demand for valve balls in renewable energy applications is expected to grow as the energy transition progresses. However, challenges remain in optimizing valve designs for specific applications, balancing cost with performance, and integrating advanced materials that can extend valve lifespans under bad conditions.

Manufacturers continue to explore new materials and surface treatments to improve valve resilience against cavitation, abrasion, and chemical attack. Advances in actuator technologies and smart valve controls also promise enhanced system integration and operational intelligence.

Ball valves are fundamental components in renewable energy systems, ensuring safe and efficient flow control across various applications. The growing emphasis on advanced ball valves reflects the need for durability and reliability under demanding conditions. Automated ball valves are transforming operational control, enabling remote management and predictive maintenance. Meanwhile, 3 way stainless steel ball valves provide versatile flow solutions that meet complex fluid handling requirements. Together, these valve technologies support the ongoing expansion and optimization of renewable energy infrastructures worldwide.

English

English Español

Español Deutsch

Deutsch