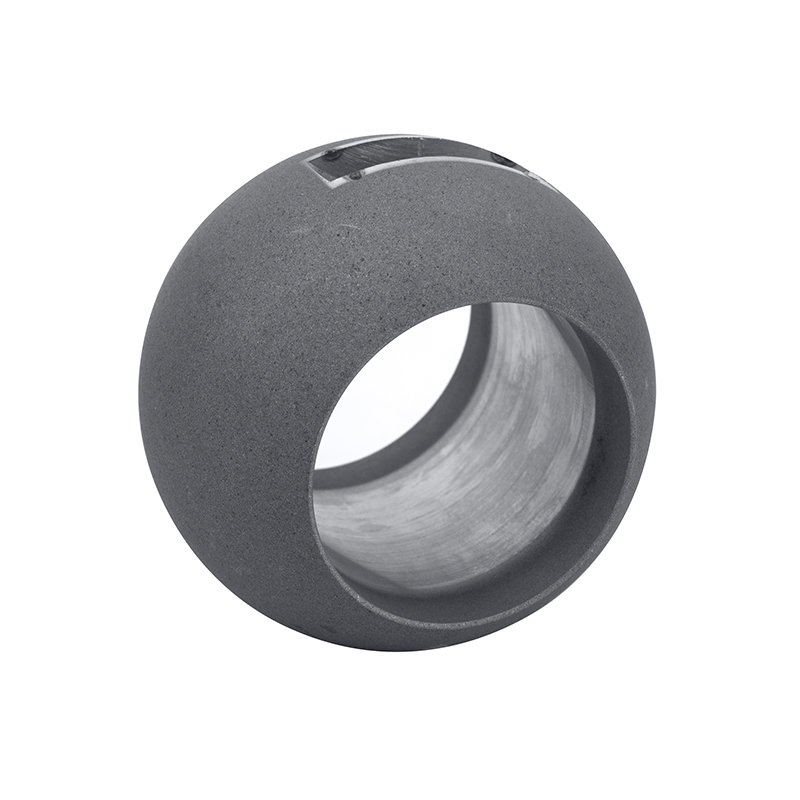

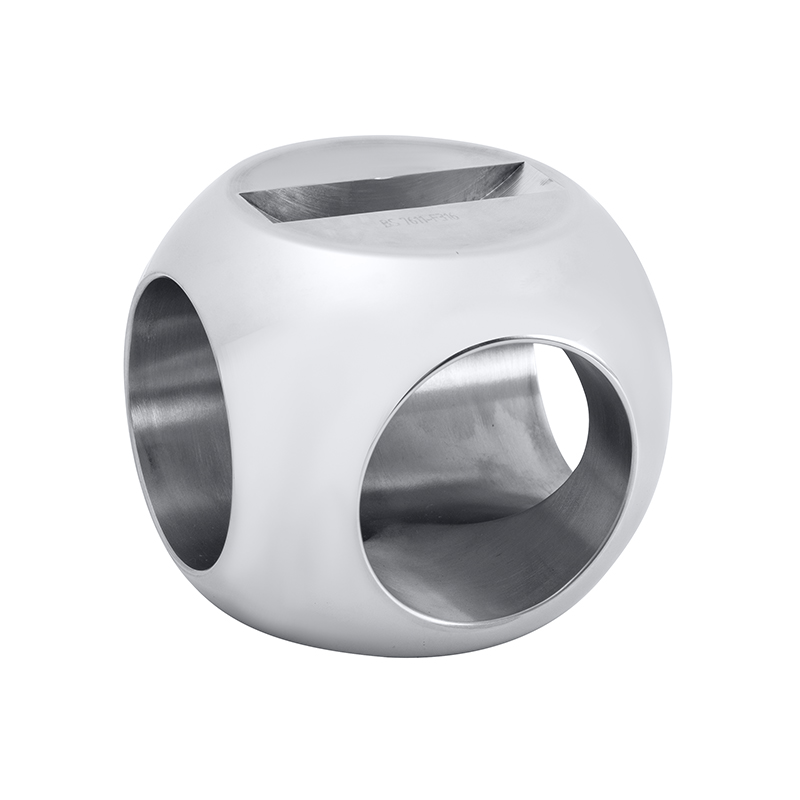

In the valve manufacturing industry, the quality and performance of valve balls are critical to the functionality and durability of the end product. Valve balls serve as the main control element within ball valves, regulating flow by rotating inside the valve body. Specialty steel plays a pivotal role in crafting these components due to its mechanical strength, corrosion resistance, and precision machinability. However, sourcing the appropriate specialty steel for valve balls presents several challenges, especially when considering products such as brass ball valves, three valve assemblies, and ball stem valves.

The Role of Specialty Steel in Valve Balls

Valve balls must withstand significant pressure and repeated cycles of operation without degrading. Specialty steel grades, including stainless steels and other corrosion-resistant alloys, provide the necessary hardness, wear resistance, and chemical stability. Unlike brass ball valves, which utilize brass primarily for its machinability and corrosion resistance in less demanding applications, steel valve balls are often required for more severe service conditions, including high pressure, temperature variations, and exposure to harsh chemicals.

Sourcing Complexities for Specialty Steel

One of the primary challenges in sourcing specialty steel for valve balls is ensuring consistent material quality. Variations in chemical composition or microstructure can advance to reduced mechanical performance or unexpected corrosion, affecting valve reliability. Suppliers must adhere to stringent standards and certifications, yet discrepancies still arise due to differences in production methods or raw material sourcing.

Furthermore, the demand for specialty steels with specific heat treatment or surface finish requirements complicates procurement. For instance, ball stem valves often require finely polished valve balls to reduce friction and prevent leakage. Achieving this finish demands steel grades capable of precise machining and surface treatment, limiting the number of suppliers who can meet these specifications.

Material Selection for Brass Ball Valve vs. Steel Valve Balls

Brass ball valves are common in residential plumbing and low-pressure industrial settings because brass offers good corrosion resistance in water and air systems, alongside ease of machining. However, brass’s mechanical properties may not be sufficient for higher-pressure or more aggressive environments, which advances manufacturers to turn to specialty steel options.

In contrast, steel valve balls used in three valve configurations or ball stem valves typically face more demanding environments. The three valve setup, which often integrates two valves and a connecting piping section for system isolation and maintenance, requires reliable valve balls that maintain integrity under repetitive operation. Specialty steel’s enhanced strength and durability make it a preferred choice in such assemblies, where failures can cause significant operational downtime.

Supply Chain Constraints

Global supply chain fluctuations have affected the availability and pricing of specialty steel in recent years. Factors such as raw material shortages, geopolitical tensions, and transportation bottlenecks have contributed to delays and increased costs. These issues impact the procurement of steel for valve balls, forcing manufacturers to adjust advance times and inventory strategies.

Manufacturers of ball stem valves, which rely on precision components, are particularly vulnerable to these supply chain disruptions. Delays in receiving specialty steel can stall production lines, affecting delivery schedules. Additionally, fluctuating steel prices may advance to budgetary constraints or the need to explore alternative material options, which must be carefully evaluated for performance compatibility.

Quality Assurance and Testing

Given the critical role of valve balls in product safety and performance, rigorous quality assurance practices are essential. Specialty steel suppliers must provide detailed material certifications, including chemical analysis and mechanical testing reports. Incoming material inspections often involve hardness tests, microstructural examinations, and corrosion resistance evaluations.

For brass ball valve manufacturers, quality checks focus on material uniformity and machinability, whereas for specialty steel valve balls, the emphasis shifts towards mechanical strength and surface finish. In assemblies like three valve systems, where multiple components interact, ensuring material compatibility and reliability is crucial to avoid premature failures.

Future Trends in Sourcing

The industry is gradually moving towards greater material traceability and sustainable sourcing practices. Manufacturers and suppliers are increasingly adopting digital tracking and certification technologies to guarantee the authenticity and compliance of specialty steel materials. This shift aims to mitigate risks associated with counterfeit or substandard materials, which can severely compromise valve performance.

Additionally, innovation in steel alloys continues, with research focused on enhancing corrosion resistance and reducing weight without sacrificing strength. These advancements may advance to new material options for valve balls, potentially easing some of the current sourcing challenges.

Sourcing specialty steel for valve balls remains a complex task influenced by material quality demands, supply chain variability, and stringent manufacturing standards. Whether producing brass ball valves for less demanding applications or specialty steel balls for three valve systems and ball stem valves, manufacturers must navigate these challenges carefully to maintain product reliability and performance. Ongoing industry developments and improvements in supply chain transparency are expected to gradually improve sourcing conditions, supporting the evolving needs of valve manufacturing.

English

English Español

Español Deutsch

Deutsch