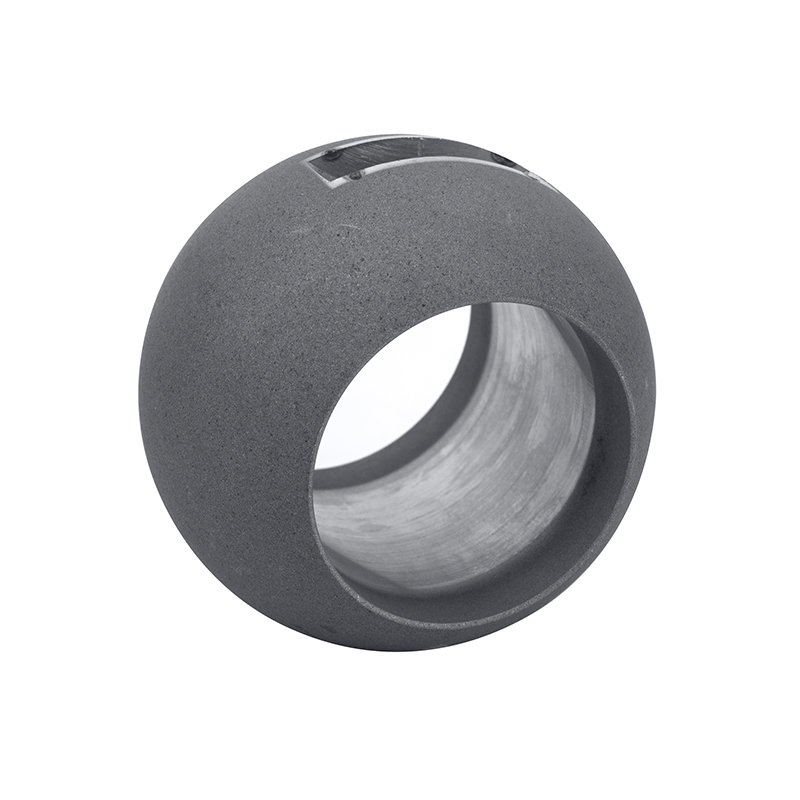

Valve balls are a critical component in fluid control systems, especially in products such as the SS three way ball valve and full port gas valve. Their role in managing the direction and flow of gases and liquids makes them indispensable in industrial applications. However, when not in use, proper storage becomes essential to ensure their longevity, performance, and safety when eventually installed. Improper handling or storage may advance to corrosion, deformation, or contamination, ultimately affecting the functionality of the entire valve system.

This article outlines the recommended storage methods for unused valve balls, particularly those used in stainless steel three-way ball valves and full port gas valves.

1. Clean Before Storage

Before storage, valve balls should be thoroughly cleaned. This step helps remove any residual grease, metal particles, moisture, or chemical substances that could react over time. For valve balls meant for use in SS three way ball valves, it is especially important to ensure all stainless steel surfaces are free of contaminants that might cause pitting corrosion or staining.

Use a mild solvent or degreasing solution compatible with stainless steel or brass (commonly used in full port gas valves). Once cleaned, the valve balls should be dried completely using compressed air or a clean, dry cloth.

2. Protect from Moisture and Corrosive Environments

Moisture is one of the main causes of corrosion, especially for metal components stored over long periods. Even though stainless steel offers a level of corrosion resistance, it is not immune under unfavorable conditions.

To prevent rust or oxidation:

Store the valve balls in a low-humidity environment.

Use desiccants inside storage containers to absorb ambient moisture.

Apply a thin layer of rust-preventive oil or corrosion inhibitor on the surface of the valve balls if they will be stored for an extended period.

This is particularly important for valve balls designated for full port gas valve applications, as gas line integrity is crucial and can be compromised by corrosion or surface pitting.

3. Temperature-Controlled Storage

Both high and low temperatures can adversely affect stored valve balls. Temperature fluctuations may cause condensation inside packaging materials, pilot to corrosion.

Store valve balls in a temperature-controlled environment where sudden changes are lessened. The ideal storage temperature is typically between 10°C to 30°C (50°F to 86°F), depending on the material composition.

For stainless steel components used in SS three way ball valves, keeping a stable temperature environment ensures that the physical properties remain consistent.

4. Use Protective Packaging

Packaging plays a significant role in protecting valve balls from mechanical damage, dust, and exposure to air. Choose packaging materials that do not react with metals. Common methods include:

Polyethylene bags for individual valve balls

Foam-lined boxes for groups of valve balls

Vacuum-sealed packaging for long-term storage

Label each package with relevant information, such as size, material, and designated valve type (e.g., for use in SS three way ball valve or full port gas valve), to prevent misuse or confusion later during assembly or dispatch.

5. Avoid Physical Stress and Contact Damage

Valve balls must retain an ideally spherical shape to function properly. Any dent, scratch, or surface imperfection can cause sealing failures or leaks in the valve assembly.

Store valve balls in a way that prevents contact with other metal objects or hard surfaces. Racks, bins, or containers with soft lining or separators can be used to prevent rolling or impact damage.

This is especially critical for balls used in full port gas valves, where any damage could compromise the seal and pose safety risks during gas transport or distribution.

6. Inventory Rotation

If you store valve balls in large quantities, use a “one-in, one-out” system to ensure older components are used before newer ones. This avoids prolonged storage of any single batch, reducing the risk of degradation over time.

Additionally, conduct periodic inspections of stored valve balls to check for signs of corrosion, discoloration, or damage.

7. Documentation and Traceability

Maintain a detailed record of each batch, including:

Manufacturing date

Material specification

Intended application (e.g., SS three way ball valve or full port gas valve)

Storage date

Such documentation ensures traceability and accountability, which is important for quality control and industry compliance.

Proper storage of unused valve balls ensures that they remain in working condition and perform reliably once installed. Whether intended for a stainless steel three-way ball valve or a full port gas valve, the right storage conditions—cleanliness, moisture control, temperature regulation, and physical protection—can extend the service life of these precision components and prevent costly downtime or safety issues later.

By adopting the storage practices outlined above, manufacturers, distributors, and maintenance teams can safeguard their inventory and ensure readiness for future use.

English

English Español

Español Deutsch

Deutsch