When designing and selecting valves for industrial or residential applications, understanding the factors that influence actuation speed and control is crucial. Among these factors, the weight of the valve ball plays a significant role, especially in valves such as the 3 inch 3 way ball valve and the plastic ball float valve. These valves are widely used in fluid handling systems due to their versatility and reliability. This article explores how the weight of the valve ball impacts the valve's actuation speed and control characteristics.

Understanding the Valve Ball and Its Role

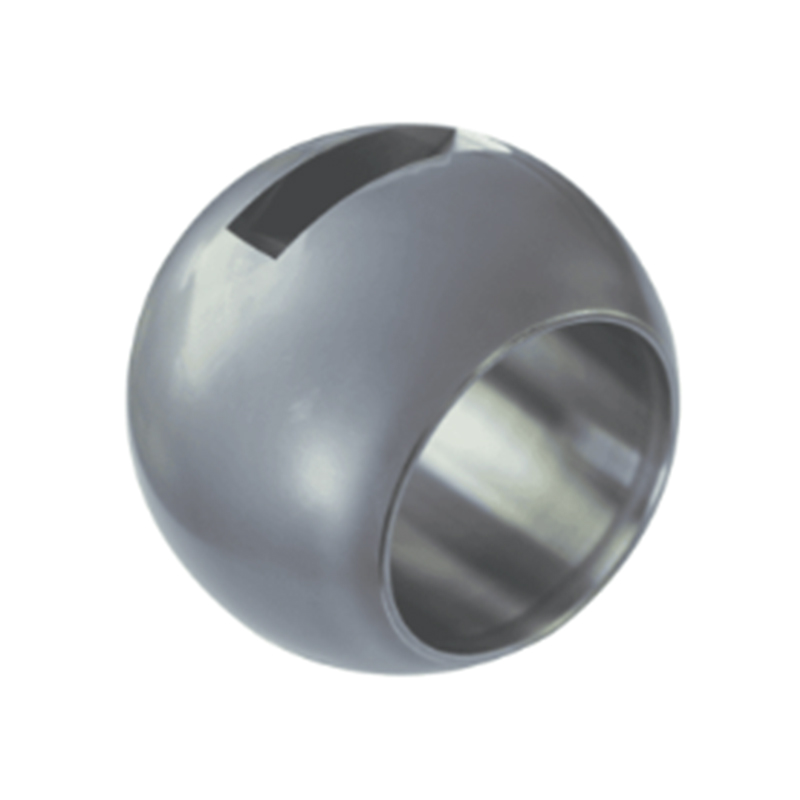

A valve ball is a spherical component inside a ball valve that regulates fluid flow. It contains a hole or port that aligns with the pipe to allow flow or rotates to block flow. The ball’s movement controls the valve's open or closed state. In the case of a 3 inch 3 way ball valve, the ball is designed to direct flow between three different ports, enabling complex flow routing in piping systems. For plastic ball float valves, the ball is typically a lightweight component that rises or falls with the fluid level to open or close the valve automatically.

The Weight Factor in Valve Balls

The weight of the valve ball affects the valve’s inertia during actuation. A heavier ball requires more torque to start or advanced movement, potentially slowing down actuation speed. Conversely, a lighter ball can be actuated more quickly but may be more sensitive to fluid pressure fluctuations or vibrations, which can affect control precision.

For a 3 inch 3 way ball valve, which is often used in systems requiring frequent switching between flow paths, the ball’s weight can influence how rapidly and smoothly the valve changes positions. If the ball is too heavy, the actuator (manual or automated) must exert more force, which could reduce responsiveness and increase wear on the actuator components over time.

Plastic ball float valves, often used in water tanks or reservoirs, rely on the buoyancy of the plastic ball to regulate fluid levels. The lightweight nature of plastic balls generally allows for quicker response to changes in fluid level, enhancing control accuracy. However, if the plastic ball is too light, it may not withstand strong flow conditions or debris, which can cause erratic valve operation.

Impact on Actuation Speed

Actuation speed refers to how quickly the valve can move from one position to another. The mass of the valve ball is directly related to the rotational inertia. For the 3 inch 3 way ball valve, increasing the ball weight increases inertia, thus requiring more energy and time to change positions. This can be a disadvantage in applications where rapid switching is needed, such as in automated fluid distribution systems.

In contrast, a plastic ball float valve, due to its low weight, typically achieves faster actuation speed in response to fluid level changes. The buoyancy effect on the plastic ball enables it to move freely and quickly, which improves the valve's ability to maintain precise fluid control.

Control Precision and Stability

Control precision in ball valves depends on the ability to position the valve ball accurately and maintain it without unintended movements. Heavier valve balls can provide greater stability once positioned because their inertia resists sudden movements caused by pressure surges or vibrations. This is advantageous in applications where maintaining a stable flow path is critical.

On the other hand, lighter balls, such as those found in plastic ball float valves, may be more prone to oscillations or fluctuations. However, the design of these valves typically accounts for this by balancing buoyancy and flow forces to ensure stable operation. The material of the plastic ball also contributes to corrosion resistance and durability, which affects long-term control reliability.

Material Considerations and Their Effect on Weight

The material of the valve ball significantly influences its weight. Metal balls, commonly used in 3 inch 3 way ball valves, have greater density, pilot to heavier valve balls. Plastic balls, used in ball float valves, are lighter and offer corrosion resistance, making them suitable for water and chemical applications.

The trade-off between weight and material properties should be carefully considered based on the application's requirements. Heavier metal balls offer mechanical strength and stability but may require more robust actuators. Plastic balls reduce actuator load and increase actuation speed but may need to be designed to withstand specific operational stresses.

Practical Implications for Valve Selection

When choosing a 3 inch 3 way ball valve, engineers must evaluate the required actuation speed and control stability. Systems needing frequent and rapid switching may benefit from lighter valve balls or actuators with higher torque capabilities to manage heavier balls effectively.

For plastic ball float valves, the emphasis is often on quick response to fluid level changes and corrosion resistance. The weight of the plastic ball must be balanced to ensure responsiveness without sacrificing durability or control precision.

The weight of the valve ball is a fundamental factor influencing the actuation speed and control of valves such as the 3 inch 3 way ball valve and the plastic ball float valve. Heavier valve balls increase inertia, potentially slowing actuation and requiring stronger actuators but offering greater positional stability. Lighter valve balls, particularly plastic ones, allow for faster response and ease of actuation but require careful design to maintain control accuracy and durability.

Understanding the relationship between valve ball weight, material, and operational requirements helps optimize valve performance for specific applications, contributing to more efficient and reliable fluid control systems.

English

English Español

Español Deutsch

Deutsch