Custom ball valve balls have undergone significant transformation through advanced manufacturing methods, enabling precise control over material characteristics and dimensional accuracy. As industries ranging from energy to food processing seek to improve fluid system efficiency, minimize operational interruptions, and meet rigorous quality requirements, manufacturing processes for valve components have progressed substantially. These technical developments convert standard components into application-specific solutions capable of addressing diverse operational demands across multiple sectors, providing industries with reliable and long-lasting valve solutions that contribute to overall system performance and maintenance reduction.

Advanced Materials for Enhanced Performance

The selection and engineering of materials have expanded considerably beyond conventional options. Specialized alloys and advanced ceramics are now tailored to specific industry requirements, providing improved resistance to wear, corrosion, and temperature variations. These materials undergo precise engineering to enhance particular properties, supporting reliable performance in challenging operational environments. The strategic material selection contributes to extended service life and consistent functionality across various industrial applications. Manufacturers continue to develop new material combinations that offer better performance characteristics while maintaining cost-effectiveness for different industrial users and their specific operational conditions.

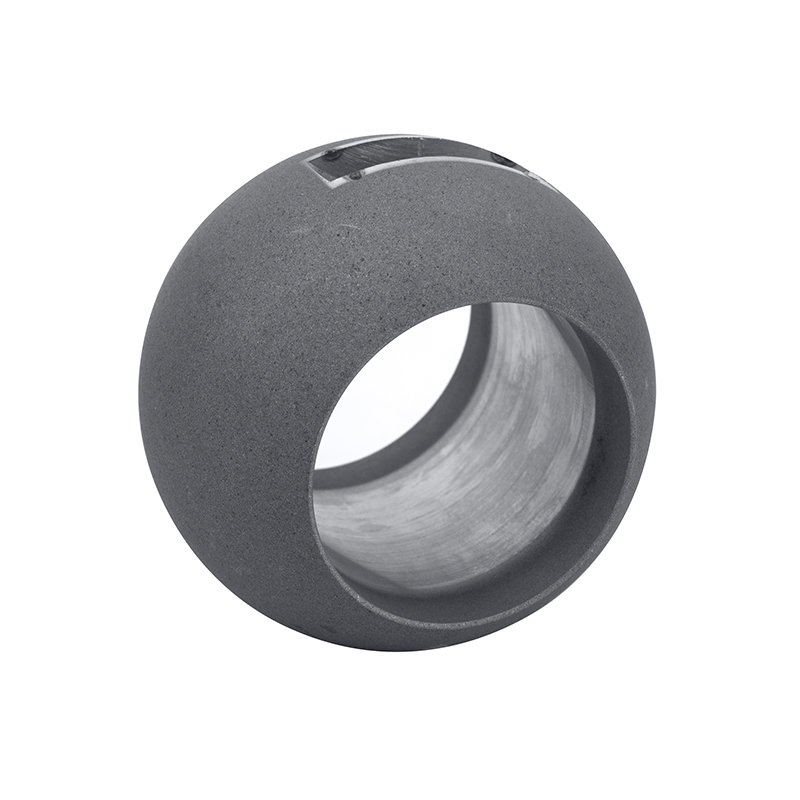

Precision Manufacturing for Consistent Quality

Modern manufacturing technologies have established new standards for dimensional precision in valve ball production. Advanced machining systems achieve tight tolerances and refined surface characteristics that directly influence operational performance. This manufacturing precision supports effective sealing capabilities in fluid systems and promotes consistent flow characteristics in processes requiring exact fluid control. The maintained dimensional stability across production batches ensures reliable integration with existing valve systems. Consistent manufacturing quality also helps reduce installation time and improves the overall reliability of fluid control systems in various industrial settings.

Surface Enhancement for Specialized Applications

Specialized surface treatments provide additional performance benefits tailored to specific industry needs. Various coating technologies create surfaces that resist material buildup, reduce wear, and comply with industry-specific standards. Finishing processes can minimize bacterial adhesion in sensitive applications while maintaining material integrity. These surface modifications extend component lifespan and support operational efficiency in demanding environments. The appropriate surface treatment selection ensures optimal performance whether in food processing, chemical handling, or other specialized industrial applications where surface characteristics significantly impact operational outcomes.

Quality Assurance Through Comprehensive Testing

Rigorous verification processes ensure manufactured components meet design specifications and quality standards. Advanced measurement systems confirm dimensional accuracy, while material analysis verifies composition consistency. Performance testing under simulated operational conditions validates functionality and durability. Industry-standard compliance protocols provide additional assurance of reliability across different application contexts, from general industrial use to specialized sectors. The comprehensive testing approach helps identify potential issues before components enter service, reducing the risk of unexpected failures in critical operations and supporting continuous operational reliability.

Adapting to Evolving Industrial Needs

Manufacturing approaches continue to evolve in response to changing industrial requirements and technological advancements. Emerging production methods enable more efficient material usage and complex geometries. Digital design tools allow performance optimization before manufacturing begins. Integration of monitoring capabilities supports predictive maintenance strategies, aligning with operational efficiency goals. These adaptive manufacturing capabilities ensure valve ball solutions remain relevant as industrial processes advance. The flexibility in manufacturing also allows for quick adaptation to new industry standards and emerging application requirements across different market sectors.

Supporting Operational Efficiency and Sustainability

The manufacturing advancements in custom ball valve balls contribute to broader operational benefits. Extended component lifespan reduces replacement frequency and associated maintenance requirements. Improved performance characteristics support energy efficiency in fluid systems. The focus on durability and reliability aligns with sustainability objectives through reduced resource consumption and waste generation. These factors combine to create value beyond immediate functional requirements. The long-term operational benefits include lower total cost of ownership, reduced environmental impact, and improved system reliability across various industrial applications and operating conditions.

Future Development Directions

The evolution of custom ball valve manufacturing continues to focus on meeting emerging industry challenges. Research and development efforts are exploring new material technologies and production techniques that could further enhance performance characteristics. The integration of digital technologies with traditional manufacturing processes offers opportunities for improved quality control and production efficiency. Collaboration between manufacturers and industrial users helps identify new application requirements and develop corresponding solutions. These ongoing developments ensure that custom ball valve balls will continue to meet the evolving needs of modern industrial operations while maintaining high standards of quality and reliability.

English

English Español

Español Deutsch

Deutsch