In modern water treatment, chemical exposure is unavoidable. From disinfectants to pH-adjusting agents, pipelines and valves face constant contact with aggressive substances. The Ball Valve Ball is designed to meet these challenges, offering superior chemical resistance and long-term reliability. Choosing the right Water Treatment Ball Valve Ball ensures that plants can operate efficiently without frequent maintenance or component failure, making it an essential part of any robust water treatment infrastructure.

Chemical Resistance for Safe Operations

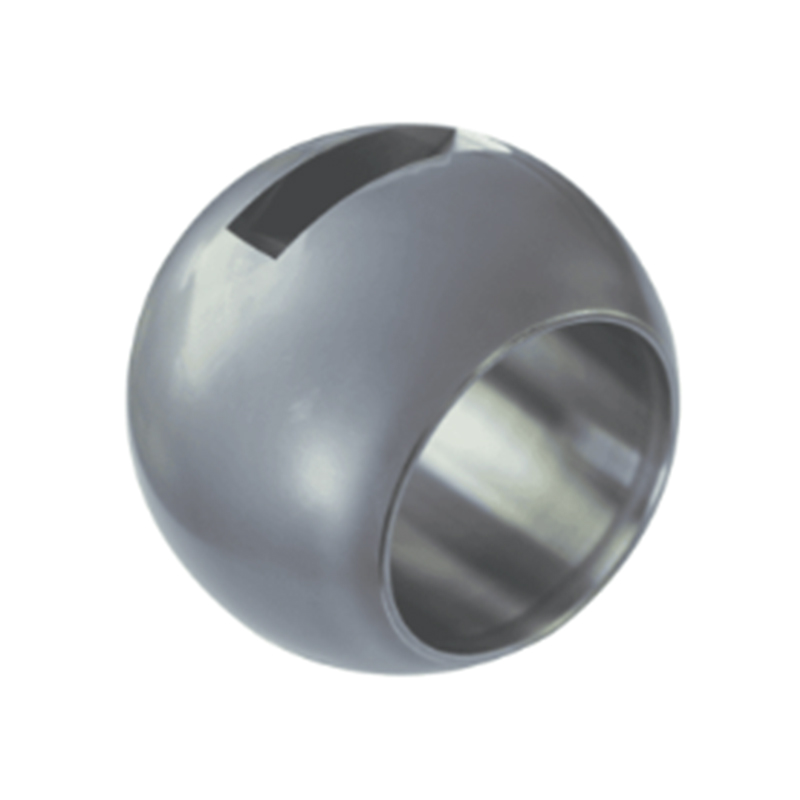

Water treatment often involves chlorine, acids, and other reactive chemicals that can corrode traditional valve components. High-quality Ball Valve Ball products are manufactured from materials such as stainless steel, coated alloys, or reinforced polymers, which resist corrosion and maintain integrity over time. This chemical resilience prevents leaks, maintains consistent flow, and reduces the risk of contamination in treated water.

Reliability Under Continuous Use

Water treatment facilities run 24/7, demanding components that can handle constant operation. A reliable Ball Valve Ball ensures smooth rotation and effective sealing even after prolonged use. Its simple spherical design minimizes mechanical wear, which is especially important when dealing with high-frequency valve operation. Reliable valves mean fewer unscheduled shutdowns, enhancing plant productivity and reducing maintenance costs.

Ease of Maintenance and Inspection

Even with robust materials, periodic inspection is necessary to maintain system efficiency. The design of Ball Valve Ball products allows for quick access and easy cleaning without major system disassembly. Technicians can replace or service balls with minimal downtime, keeping water treatment plants operational while ensuring safety and compliance with environmental standards.

Adaptable for Various Water Treatment Applications

Water treatment systems vary widely—from municipal supply networks to industrial process plants. The versatility of a Ball Valve Ball allows it to fit different valve sizes and pipeline configurations, ensuring seamless integration across various applications. This adaptability makes it a cost-effective solution for facilities looking to maintain consistent performance across diverse treatment setups.

Supporting Process Optimization

Reliable ball valves do more than control flow—they enable precise dosing and filtration. Using chemically resistant Water Treatment Ball Valve Ball components helps optimize chemical usage, prevent water loss, and maintain steady operational pressure. These factors contribute to overall process efficiency, ensuring that the plant meets performance targets while minimizing environmental impact.

Industrial Applications and Team Efficiency

Beyond chemical resistance, Ball Valve Ball components play a critical role in industrial water treatment operations. In large-scale facilities, multiple valves often operate simultaneously to control flow across complex pipelines. A high-quality ball valve ensures smooth rotation and consistent sealing, allowing teams to coordinate operations efficiently without interruptions.

In chemical dosing or filtration processes, reliable Water Treatment Ball Valve Ball products reduce the risk of sudden valve failure, which could otherwise halt production or compromise water quality. Their durability and precise design enable technicians to perform routine inspections and replacements quickly, minimizing downtime and maintaining continuous operation. This combination of chemical resilience and operational reliability makes them indispensable for modern industrial water treatment plants.

For modern water treatment facilities, selecting a durable Water Treatment Ball Valve Ball ensures chemical resistance, operational reliability, and long-term cost savings. From withstanding harsh substances to supporting process optimization and future upgrades, these ball valves are indispensable for safe, efficient, and sustainable water management.

English

English Español

Español Deutsch

Deutsch