In modern industrial applications, the demand for reliable and precise fluid control continues to grow. Among the various solutions available, at controls ball valves have gained attention for their ability to provide accurate regulation of flow in diverse systems. These valves are designed to balance efficiency and durability, addressing the unique challenges presented in chemical, water treatment, and manufacturing processes.

Engineering for Accurate Flow

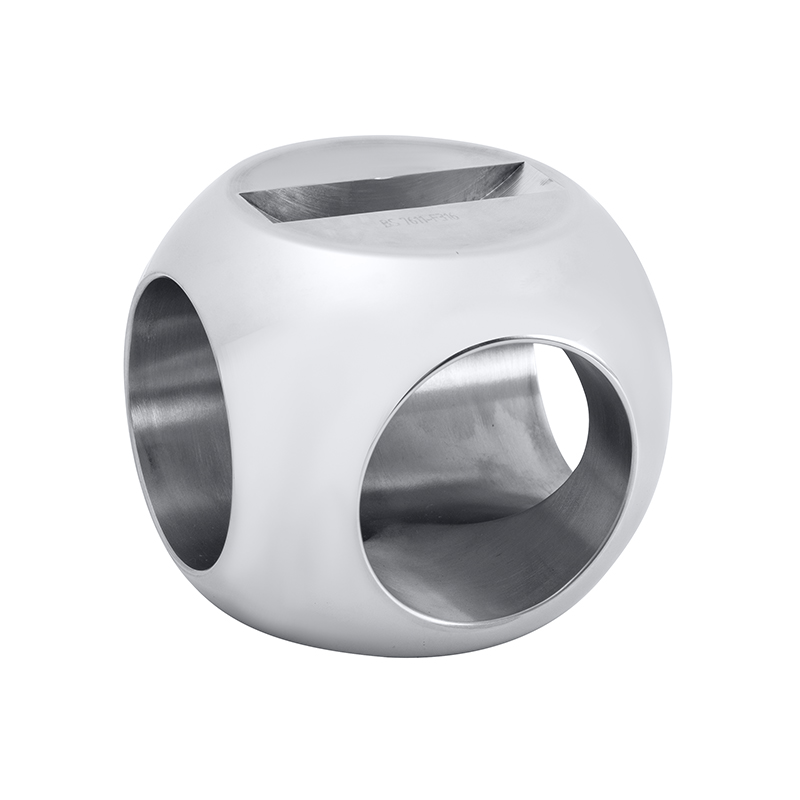

One of the main advantages of at controls ball valves is their capacity to deliver controlled flow with small deviation. Unlike other valve types, ball valves feature a spherical closure element that rotates within the valve body. This design allows for a tight seal when the valve is closed and a clear passage when it is open, reducing turbulence and maintaining steady flow. The incorporation of hard seal ball technology further enhances this precision. By using materials resistant to wear and corrosion, these seals maintain integrity over extended periods of operation, ensuring that the valve consistently performs as intended.

Applications Across Industries

At controls ball valves find applications across multiple sectors. In water distribution networks, these valves can regulate pressure while less leakage, supporting efficient delivery of clean water. In chemical processing, the use of hard seal ball components ensures compatibility with aggressive fluids, reducing the risk of contamination and enhancing safety. Manufacturing plants also benefit from the precision of these valves, as controlled flow can influence the quality of the final product and maintain consistency across production lines.

Maintenance and Longevity

An often-overlooked aspect of fluid control systems is the ease of maintenance. At controls ball valves are designed to simplify service routines. The use of hard seal ball materials less wear, reducing the frequency of replacement and lowering operational interruptions. Additionally, the straightforward construction of these valves allows technicians to inspect and service them without extensive disassembly, which is especially beneficial in complex systems with limited accessibility.

Supporting System Efficiency

Precision in fluid management is not solely about controlling flow; it also contributes to the efficiency of the entire system. Accurate valve operation can prevent pressure drops, reduce energy consumption, and improve overall reliability. By implementing at controls ball valves equipped with hard seal ball elements, engineers can achieve steady performance that meets the operational demands of modern facilities. These valves serve as a dependable component within systems that prioritize both stability and adaptability.

The role of at controls ball valves in fluid systems is significant due to their ability to deliver precise control, durability, and compatibility with various industrial applications. The integration of hard seal ball technology further strengthens these benefits, offering resilience against wear and chemical exposure. As industries continue to emphasize efficiency and reliability, the adoption of precise valve solutions plays a critical part in supporting system performance. Understanding the technical features and advantages of these valves provides valuable insights for designing and maintaining effective fluid management systems.

English

English Español

Español Deutsch

Deutsch